21

1.Output terminal (+)

Connect electrode holder when in SMAW mode; Connect with the work piece when in

TIG mode.

2.Control socket

Connect to torch trigger.

3.Output terminal (-)

Connect work piece when processing SMAW; connect with TIG torch when processing

TIG welding.

4.Water inlet

Connect water hose of TIG torch.(optional).

5.Gas outlet

Connect gas hose of TIG torch.

6.Analog control socket(optional,only ATIG***P-C welding machine has this socket)

Connect to analog remote controller or other special device.

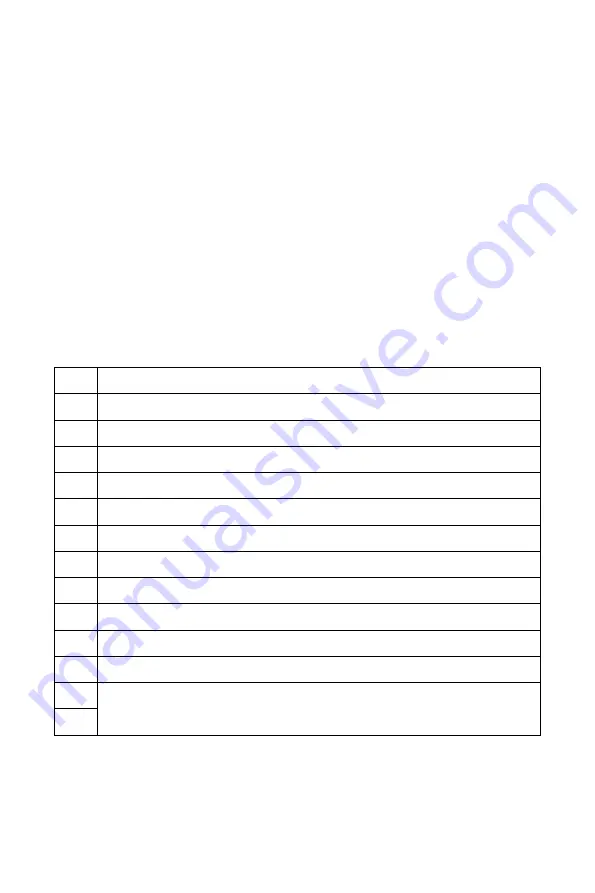

Table 4-6-1 Description of analog control socket

7.Digital remote control socket(optional,only ATIG***P-C welding machine has this

socket) Connect to digital remote controller or other 485 communication device.

Pin No.

Description

1

Chassis Ground

,

connect with shield layer of control cable.

2

Null

3

Power supply of remote control current given potentiometer:10VDC

4

Remote control current input signal (0-10VDC).

5

Remote control current GND.

6

Welding machine start signal, short circuit with pin 8 ,welding machine start

7

Gas test signal, short circuit with pin 8,the gas valve on.

8

GND.

9

Arc voltage output,0-10VDC(10V equals to 100V arc voltage).

10

Welding current output signal,0-10VDC(10V equals to Max. rated output current).

11

GND

12

Successful arc start signal: Standby: pin 12 and pin 13 open, successful arc start:

pin12and pin13 short circuit

13