Instruction Manual

–

V6.19

GYROTORK DUAL version

- 17 -

VII.

CALCULATION Settings

The GYROTORK torque gauge allows you to setup automatic calculations derived from the graph. The

settings of the calculation can be done in the Test menu. It is possible to perform 2 simultaneous

calculations in addition to raw data, the maximum and the minimum.

1.

Calculation

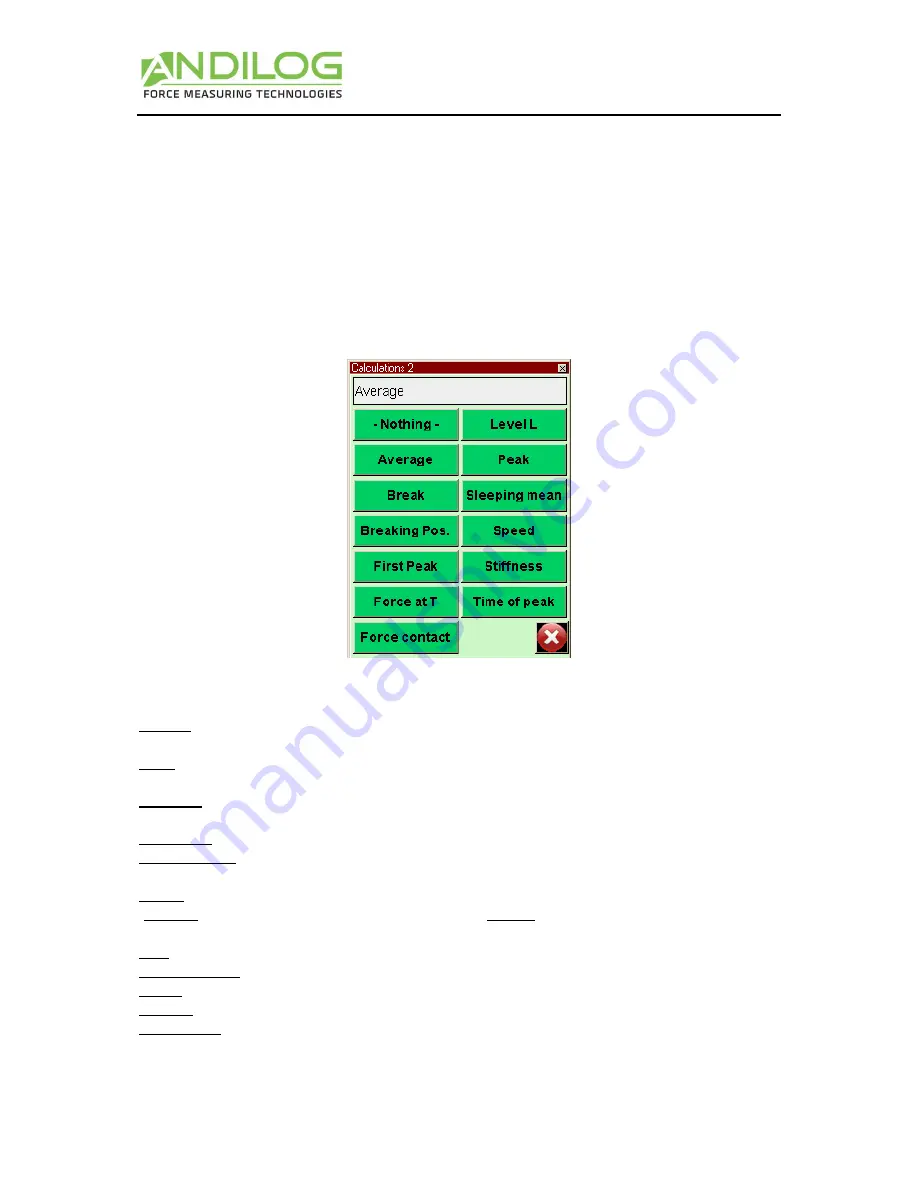

The GYROTORK allows you to select 2 calculations, derived from the graph. Select the Calculus 1 or 2

tab. The Test running mode should be activated to perform calculation.

The following calculations are available:

Average - The average of load readings over selected time or travel. Select time or travel parameters

after selecting average.

Break - The calculated break point. Select the percent of peak to determine break point after

selecting break.

First Peak

–

Select the first peak in multiple peak graphs. Select the percent of peak to determine

peak point after selecting First Peak

Torque at T -Torque at a specific time. Select time in milliseconds.

Torque contact

–

Calculates the maximum torque when

you’re

closing a contact or a switch plug on

the Input E1 (for example the external button on the wrench).

Level L

–

Calculates the value of a channel, when the other channel has reached its defined limit

(absolute: the time increments when the test starts / relative: the time increments when the curve

starts, meeting the start condition on torque value, to be used for Top load tests)

Peak

–

The maximum torque or torque measured during the test.

Moving average

–

Rolling average or running average

Speed: Speed calculation in real time of the selected channel

Stiffness: Calculate the slope of the curve between two values

Time of peak: Return the time value when the peak have been reached