- 46 -

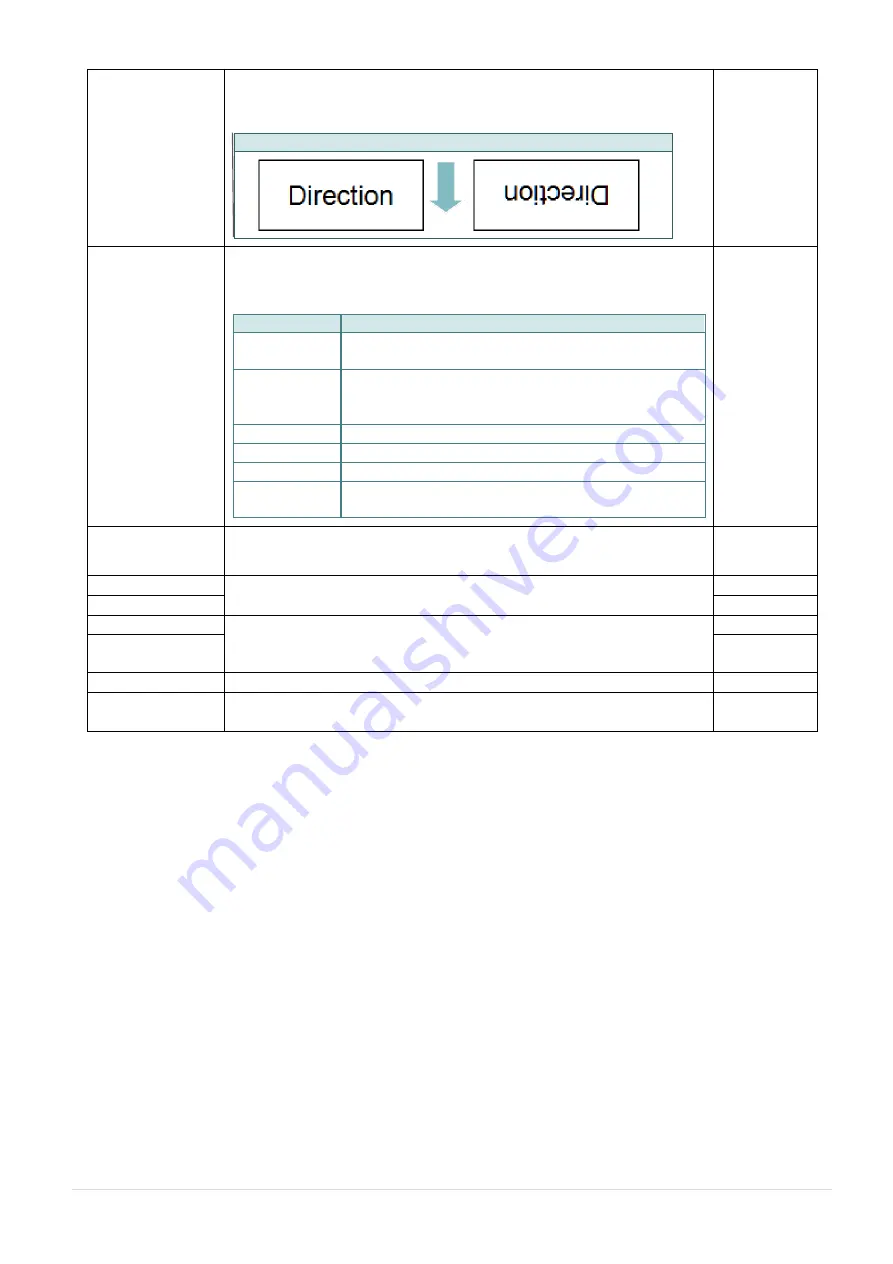

Direction

The direction setting value is either 1 or 0. Use this item to setup

the printout direction.

0

Print mode

This item is used to set the print mode. There are 6 modes as

shown below,

Batch

Mode

Offset

This item is used to fine tune the media stop location.

Available setting values range from -999 dots to 999 dots.

0 dot

Shift X

This item is used to fine tune the print position

.

Available

setting values range from -999 dots to 999 dots.

0 dot

Shift Y

0 dot

Reference X

This

item is used to set the origin of the printer coordinate

system both horizontally and vertically.

Available setting

values range from 0 dots to 999 dots.

0 dot

Reference Y

0 dot

Code page

Use this item to set the code page of international characters set.

850

Country

Use this option to set the country code. Available setting

values range from 1 to 358.

001

Note: If printing from enclosed software/driver, the software/driver will send out the

commands, which will overwrite the settings set from the panel.

DIRECTION 0

DIRECTION 1

F

EE

D

Printer Mode

Description

None

Next label top of form is aligned to the printhead

burn line location. (Tear Off Mode)

Batch Mode

Once image is printed completely, label gap/black

mark will be fed to the tear plate location for tear off.

Peeler Mode

Enable the label peel off mode.

Cutter Mode

Enable the label cutter mode.

Cutter Batch

Cut the label once at the end of the printing job.

Rewinder

Mode

Enable the label rewinder mode.