Date: 02 Feb 2011

Ampair ® 300 (Mk1, “Pacific”) Wind Turbine Manual

CD 2300

Issue: 1.2

Page 8 of 34

- 8 -

© Ampair, April 2007

Rotor speed

500-1400 rpm

Generator type

Permanent magnet, three phase with external rectifier

(rare earth neodymium magnets)

Nominal voltage

12 volt DC or 24 volt DC

Speed regulation

Blade pitch control above 13 metres per second

(27 knots, 30 miles per hour)

Power regulation

Blade pitch control above 13 metres per second

Brake

Generator short circuit (optional 'stop' switch)

Weight

12 kg

Housing

Die cast aluminium (powder coated)

Colour

White with red hub (other colours available on request)

Rotor thrust (at 20 metres per second)

160 Newtons

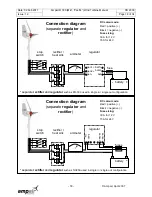

3.3 System description

The Ampair 300 is a wind driven generator (a wind turbine) capable of supplying up to 300 Watts of

electrical power at either 12 or 24 volts for charging batteries. A complete system includes the generator,

the rectifier, the field wiring, and normally a stop switch and a regulator, plus of course batteries and a

mounting.

3.3.1 The generator

The unit consists of a two part cast aluminium body, the two parts sealed by an "O" ring. One twelve pole

permanent magnet rotor runs on a stainless steel shaft. The shaft runs in two sealed grease-packed ball

bearings. One three phase stator is located within the body.

The three phase alternating current output of the stator passes to three carbon brushes mounted in brush

holders located behind the lower body section, accessible through the electrical cover plate. The carbon

brushes carry the output to three brass slip rings mounted on the stationary pivot shaft, allowing the

machine to rotate to follow the wind. The output is electrically isolated from the case.

The body is mounted on the pivot shaft where it runs on sealed grease packed ball bearings at the top

and a composite plain bearing at the base. The top bearing is captive in the body; the lower bearing is

located in the body by a stainless steel spiral retaining ring. The pivot section contains an "O" ring around

the lower bearing to body junction and a "V" seal where the pivot shaft passes through the lower bearing.

The pivot axis passes through the centre of gravity of the assembled machine. This is necessary to

ensure alignment into the wind in light breezes without undue spinning, and to allow the wind turbine to be

used on small boats.

The ro

tor disc and hub together make up the unique PowerFurl™ furling mechanism. The three

cambered

and twisted glass reinforced polyester (GRP) moulded blades have been designed to be perfectly

balanced and aerodynamically and acoustically efficient. They are mounted on an aluminium hub (shaped

like a nose cone).

The purpose of the PowerFurl™ furling mechanism is to simultaneously twist all three

blades along their axis when the wind speed becomes excessive, whilst still keeping the wind turbine

facing into the wind and generating power. The three special pitching weights form an integral part of the

PowerFurl™ mechanism.

The hub is fitted to the generator shaft by an M10 cap screw.

The blades have a relatively broad root section to enable them to start up in low wind speeds. This is

important as for much of the time the wind only blows at low speeds. The blades are of a rigid construction

to minimise pulsating aerodynamic noise caused by blade deflection (fluttering)

An aluminium alloy tail vane is clamped to the rear of the generator body using three M8 x 25mm stainless

steel screws, six plain washers and three lock nuts. The tail vane is provided with a grab hole at its lower

corner to facilitate turning the unit cross-wind to stop the wind turbine rotating when required (e.g. using a

boat hook).

All Ampair 300 units are constructed of marine grade materials. All aluminium parts are alacromed and

powder coated inside and out, or anodised. All other parts are stainless steel or composite, except for

elastomers.