©Copyright AMKUS Rescue Systems, Inc. 2020

LAL-001 August 11, 2020 Rev01

9

5.0 SAFETY CONSIDERATIONS

5.1 PROTECTIVE CLOTHING

WARNING

Tool operators bear responsibility for ensuring use of appropriate protective clothing and

equipment. The chosen protective clothing and equipment must provide protection from potential

hazards users may encounter while operating AMKUS rescue tools. Requirements for protective

clothing and equipment are determined by the Authority Having Jurisdiction (AHJ).

5.2 TRAINING

AMKUS tools facilitate the extrication of entrapment victims. Only trained emergency services personnel should attempt victim

extrication. All personnel using AMKUS rescue tools are assumed to have completed a training course covering safe extrication of

entrapment victims. The training must be acknowledged as educationally sound by the local Authority Having Jurisdiction (AHJ) over

such training.

5.3 OPERATING CONSIDERATIONS

NOTICE

AMKUS tools are intended for intermittent use. Allow su

ffi

ciently long pauses for the rescue

tool to cool. If the tool’s exterior becomes too hot to touch, the temperature is likely above 120°F

(49°C). An overheated rescue tool operates less e

ff

ectively. When hydraulic oil temperature

reaches 158°F (70°C), the tool’s e

ffi

ciency drops signi

fi

cantly, and the tool should be stopped to

cool down.

To avoid rescue tool overheating:

• After use, clean o

ff

any accumulated oil, grease, dirt, or corrosive substances with a damp cloth and soapy water.

NOTICE

Operating the rescue tool continuously against an end stop may cause overheating resulting

in an inoperable tool. Permanent damage to the tool may occur. When an end stop is reached,

release the control handle to return the control to the neutral position.

6.0 SET-UP PROCEDURE

Normally, AMKUS equipment is prepared and serviced by your dealer prior to delivery. If, however, you have decided to place the

equipment into service yourself, remove equipment from the packing cartons and carefully inspect for damage. Damage that occurs

during shipment should be reported immediately to the carrier.

1. Gather and review all safety and use documentation prior to operating any rescue tool.

2. Connect the tool connection hoses to the hose lines from the AMKUS hydraulic power unit.

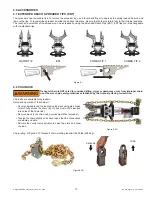

A. Standard Couplings: Please note that the male and female couplings on the hose lines leading from the power unit should

be connected to the corresponding male and female couplings on the tool connection hoses. To connect the couplings, twist

the sleeve on the female coupling so that the notch in the sleeve lines up with the pin. Push the sleeve back so the pin

fi

ts

into the notch. While holding the sleeve back, push the male coupling into the female coupling. Release the sleeve; it will

spring forward into place. Twist the sleeve 1/4 turn so that the pin no longer lines up with the notch. Pull on the couplings to

check that they are securely connected.

B. Mono Couplings: Please note that the female coupling on the hose lines leading from the power unit should be connected

to the corresponding male coupling on the tool connection hoses. To connect the couplings, place the male coupling into

the female coupling. Rotate clockwise until you feel the coupling latch. Pull on the couplings to check that they are securely

connected.

In most cases, the Mono Couplings can be connected and disconnected while the hose line is under

fl

ow. It is usually not

necessary to place the directional control of the power unit in the neutral position before connecting and disconnecting.

However, certain circumstances such as back pressure in the return line and/or cold temperatures, may make connecting

and disconnecting under

fl

ow extremely di

ffi

cult or impossible. If you are unable to connect and disconnect while the line is

under

fl

ow, place the directional control valve of the power unit in the neutral position and then disconnect or connect.