©Copyright AMKUS Rescue Systems, Inc. 2020

LAL-001 August 11, 2020 Rev01

14

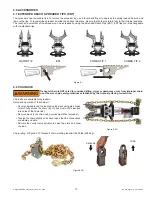

9.0 SAFETY GUARDS

Tools with moving blades have a guard over the moving parts. The guard is secured with screws which can be removed to clear

debris during maintenance. Replace guards after maintenance.

Figure 9.0

10.0 MAINTENANCE

PERIODIC MAINTENANCE SCHEDULE

Frequency

(Hours of Use)

Operation

Method

Person in

charge

AFTER EACH USE

CHECK BLADES, TIPS AND ARMS FOR WEAR or DAMAGE

Visual

O

EVERY 8 HOURS

CHECK THE TOOL FOR DAMAGE, VERIFY OPERATING

CONTROLS BEFORE AND AFTER EACH USE

Visual

O

ENSURE ALL SNAP RINGS, NUTS, AND BOLTS ARE

SECURE

Visual and

Hand Tools

O

Table 10.1

WARNING

Perform all maintenance, inspection, and cleaning operations after the tool is cooled down to

avoid injury or damage to the tool (see the Responsible Party in the maintenance schedule).

Clean and inspect the tool before starting any maintenance work.

Annual tool maintenance shall be completed regardless of how many hours the tool has been

used since its last maintenance.

10.1 ROUTINE MAINTENANCE

10.1.1 CHECK THE BLADES

The use of damaged blades decreases the cutting e

ffi

ciency of the tool and can overheat the tool.

Replace the blades when they become worn, cracked, or gouged. (Consult AMKUS Rescue Systems)

Check the torque on the cutter & combination tool pivot bolt monthly. Proper pivot bolt torque is 120 ft-lbs (163 N-m).

10.1.2 HYDRAULIC MAINTENANCE

Inspect the tool and hydraulic hoses for leaks. Inspect the hydraulic hoses and couplers for debris, damage, and proper operation.

Replace any damaged components. Remove the tool from use if damaged. Contact your local dealer or amkus.com for repairs.

10.1.3 LUBRICATION

Cutter blades, combi blades, spreader arms, links, and pins are lubricated with white lithium grease. Annual re-lubrication is

recommended for average service conditions. More frequent lubrication may be required for severe or frequent usage conditions.