57

Operation

Ramping Functions Example

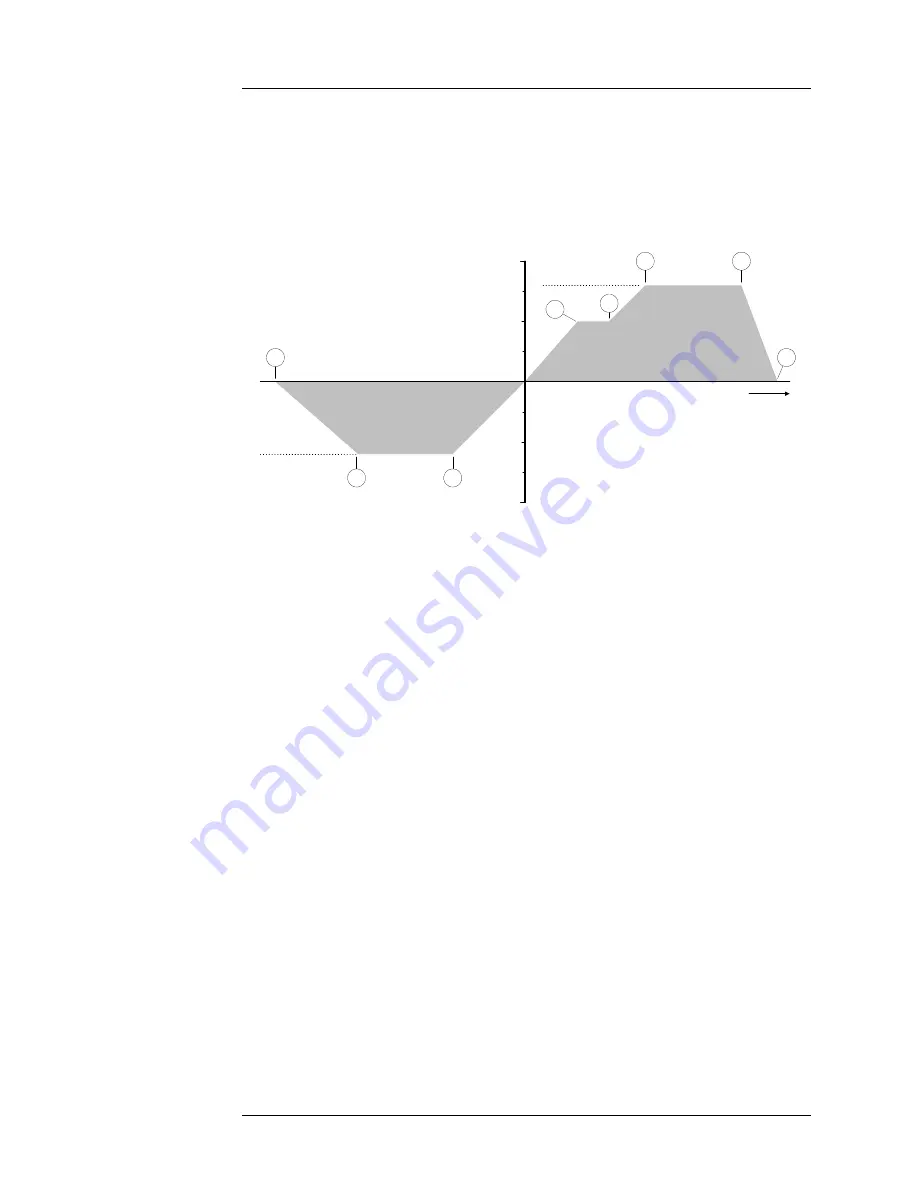

3.3.6 Ramping Functions Example

As an example of ramping to two programmed current settings, refer to

Figure 3-6 below. Each step is labeled as 1 through 8 in Figure 3-6. The

Model 420, for the purposes of the example, is assumed to be in the

PAUSED mode at 0 A at the beginning of the ramp.

Point 1. The operating current is 0 A and the Model 420 is in the PAUSED

mode. The operator sets the programmed current to -30.000 A. The

5$03

3$86(

key is pressed so that the PAUSED mode is no longer active and

the Model 420 begins ramping current.

Point 2. The programmed current setting of -30.000 A is achieved and the

Model 420 switches to HOLDING mode.

Point 3. The operator increases the ramp rate setting. The operator also

keys in a new value of +40.000 A for the programmed current setting. As

soon as the new programmed current is entered, the Model 420

automatically begins ramping at the specified ramp rate.

Point 4. The operator presses the

5$033$86(

key at an operating

current of 25.15 A and the PAUSED mode is activated. The Model 420

maintains the operating current in the PAUSED mode.

Point 5. The operator presses the

5$033$86(

key once again to resume

ramping.

Point 6. The programmed current setting of +40.000 A is achieved and the

Model 420 switches to HOLDING mode. At this point the operator

deactivates the persistent switch heater which removes the magnet from

the circuit.

1

4

6

7

8

2

3

PROGRAMMED

CURRENT 1

50 A

-50 A

PROGRAMMED

CURRENT 2

Time

5

Figure 3-6. Example of ramping to two different programmed current settings.

Summary of Contents for 420

Page 2: ......

Page 4: ......

Page 6: ......

Page 12: ...x Rev 7 List of Tables ...

Page 18: ...xvi Rev 7 Foreword Safety Summary ...

Page 22: ...4 Rev 7 Introduction Front Panel Layout ...

Page 24: ...6 Rev 7 Introduction Rear Panel Layout ...

Page 30: ...12 Rev 7 Introduction Operating Characteristics ...

Page 54: ...36 Rev 7 Installation Power Up Procedure ...

Page 82: ...64 Rev 7 Operation Summary of Operational Limits ...