16

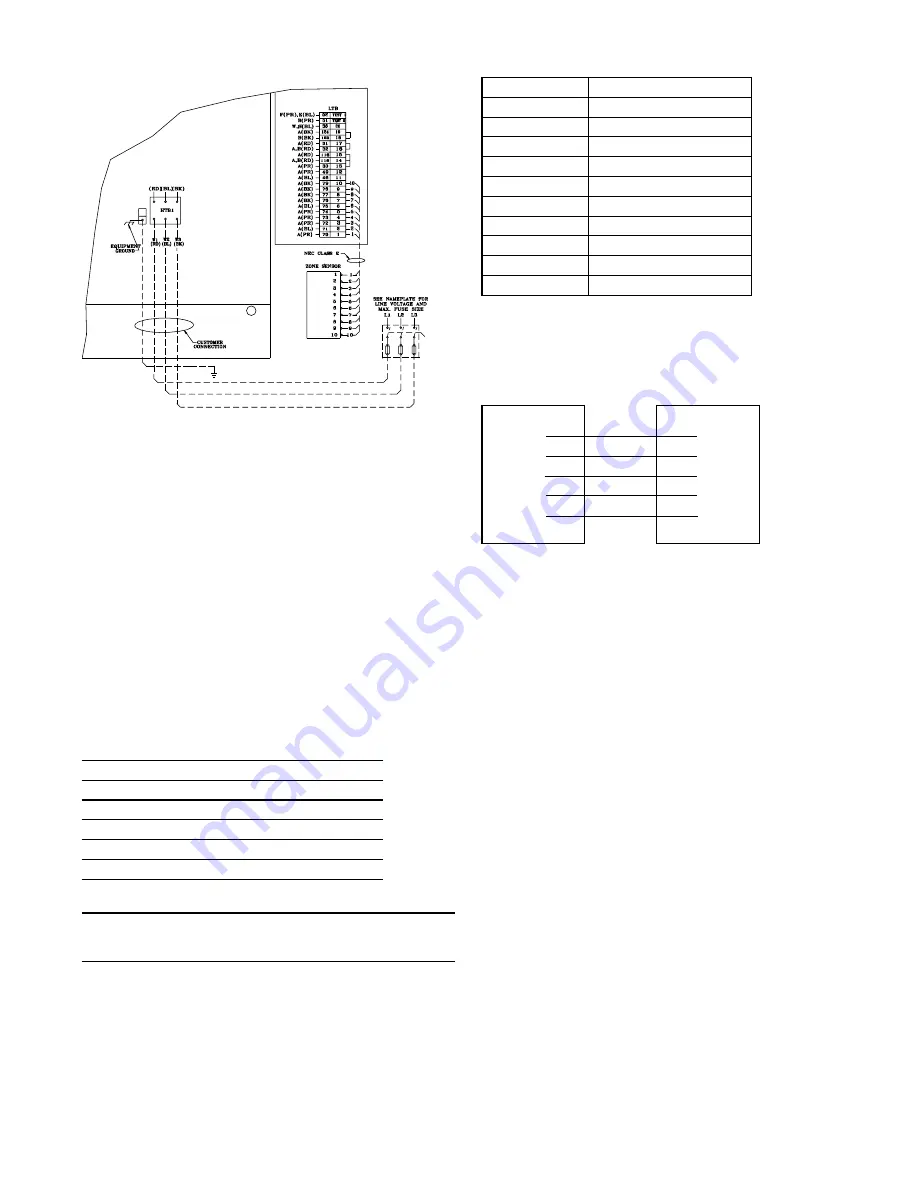

Figure 10

Typical Field Wiring Diagram

Low voltage control wiring must not be run in conduit with

power wiring. Route low voltage wire from zone sensor termi-

nals through 7/8 inch bushing in the unit. See dimensional

data for control wire entry location. Make connections as

shown by the appropriate low voltage wiring diagrams in Fig-

ure 10.

Zone Temperature Sensor conductors are standard thermostat

wire. The only exceptions are Tracer/Tracker installations

which utilize a serial communications link and require a

shielded twisted pair of conductors between the Tracer/

Tracker and the (TCI) Communications Interface.

Recommended wire sizes and lengths for installing the Zone

Temperature Sensor are provided in Table 5. Ensure that the

wiring between the controls and the unit's termination point

does not exceed two and a half (2.5) ohms/conductor for the

length of the run. Resistance in excess of 2.5 ohms per con-

ductor can cause deviation in the accuracy of the control.

Table 5.

DC Conductors

Wire size (mm2)

Maximum wire length (m)

0.33

45

0.50

76

0.75

115

1.30

185

2.00

300

NOTE: Do not run the electrical wires transporting DC

signals in or around conduit housing high voltage

wires.

Zone Temperature Sensor and low voltage terminal

designations are no longer R-W-Y-G-B etc, they are now 1-2-3

etc. Connections should be made using 1 to 1, 2 to 2, 3 to 3,

and so on. See following example.

Zone Temperature Sensor Terminal Strip

Terminal #

Terminal I.D.

1

ZTEMP

2

SIGNAL COMMON

3

CSP

4

MODE

5

HSP

6

LED COMMON

7

HEAT LED

8

COOL LED

9

SYS ON LED

10

SERVICE LED

Zone

Low

Sensor

Voltage

Module

Terminal Board

(ZSM)

(LTB)

1 [ ]

[ ] 1

2 [ ]

[ ] 2

3 [ ]

[ ] 3

4 [ ]

[ ] 4

5 [ ]

[ ] 5

Emergency Shut Down

For Emergency Shut Down, remove the jumper between LTB-

16 and LTB-17 and install normally closed contacts (Open at

Fault Condition). Immediate shut down will occur and the UCP

will be disabled.

Compressor Disable

To disable Compressor #1, remove the jumper between LTB-

13 and LTB-14 and install normally closed contacts (open to

disable).

To disable Compressor #2, (if applicable), remove the jumper

between LTB-14 and LTB-15 and install normally closed con-

tacts (open to disable).

Scroll Compressors

(125 - 250 Units only)

Because scroll compressors are uniquely different from tradi-

tional reciprocating compressors, their operating characteris-

tics and requirements represents a departure from reciprocat-

ing compressor technology.

Proper phasing of the electrical power wiring is critical for

proper operation and reliability of the scroll compressor.

Proper rotation of the scroll compressor must be established

before the unit is started. This is accomplished by confirming

that the electrical phase sequence of the power supply is cor-

rect. The motor is internally connected for clockwise rotation

with the inlet power supply phased A, B, C.

Summary of Contents for YK-IOM-2

Page 10: ...10 Figure 5 Figure 6 Detail of the Gas Section...

Page 17: ...17 Figure 11A Zone Sensor Interconnections...

Page 18: ...18 Figure 11B Conventional Thermostat Interconnections...

Page 23: ...23...

Page 24: ...24...