14

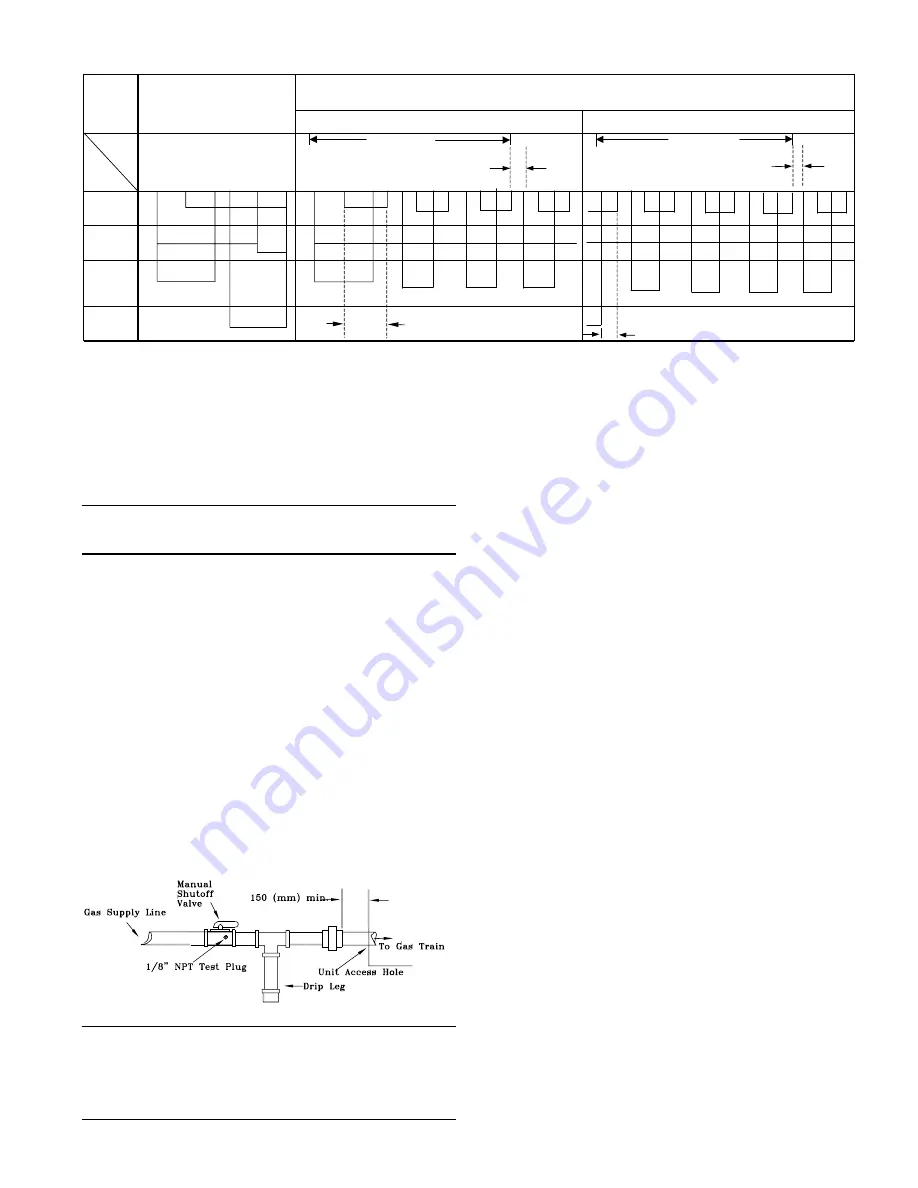

Figure 7- Trane Gas Heating Module Ignition Controller Start and Safety Sequence

Normal Sequence

Sequence With Safety Measures

(Stop by Regulation)

At Ignition with Flame Signal Fault

At Disappearance of Flame Signal

Time (s)

3 Retries 186.3 s

3 Retries 186.3 s

Operations

0

54

59.

7

60.

9

Manuel

R

egul

at

io

n

0

54

59.

7

62.

1

72min

etc..

0

0,

98

2

55

59.

7

62.

1

72min

etc..

Gas Valve

Fan

Electrode

Heating

Ionisation

TSA = 8,1s

TSE = 0,96S maxi

Use the following steps to complete the installation of the unit

gas piping. (See Figure 8)

1. Install a tapped, style A (1/8 inch NPT tap) shut-off gas cock

at the end of the gas supply line near the unit. Be sure the

tapped gas cock is downstream of the pressure regulator, if

used.

Note: The shut-off gas cock must be installed

outside the unit, and should meet the specifications

of all applicable National and Local Codes.

2 . Install a ground union joint downstream of the shut-off

cock. This joint must be installed outside of the unit.

3 . Install a drip leg (at least 150 mm (6") in depth) next to the

union as shown in Figure 8. This drip leg is required to col-

lect any sediment that may be deposited in the line.

4 . Before connecting the piping circuit to the unit, bleed the air

from the supply line. Then cap or plug the line and test the

pressure at the tapped shut-off cock. The pressure reading

should not exceed 35 mBar (14 inches water column).

5. Connect the gas piping to the unit. Check the completed

piping for leaks using a soap and water solution, or equiva-

lent.

Figure 8

Gas Piping Schematic

IMPORTANT NOTE: THIS UNIT USES A NEGATIVE

REGULATION GAS VALVE. AT START-UP, THE

OUTLET PRESSURE SHOULD BE CHECKED AND

ADJUSTED IF REQUIRED TO A (NEGATIVE) -50Pa (-

0.2" OF WATER COLUMN.) NEVER ADJUST THE

REGULATOR TO A POSITIVE PRESSURE.

Manifold Pressure

The unit manifold pressure regulator (located on the gas

valve) is factory installed and adjusted to provide the rated unit

heating capacity. The required manifold pressure is factory set

at (negative) - 50 Pa (2 inches of water column) for natural

and LP gas.

Check the manifold pressure at the unit gas valve. Do not ex-

ceed the recommended pressure shown on the unit name-

plate.

Filter Installation

To gain access to filters, remove the evaporator fan access

panel. Each unit ships with 50 mm (2") filters. Number and

size of filters is determined by size and configuration of the

unit. Refer to the unit “Service Facts” for filter requirements.

Evaporator Fan Adjustment

Use the following procedure to determine the proper adjust-

ment of the evaporator fan sheaves for a specific application.

1. Determine total system external static pressure Pa (inches

of water column) with accessories installed. To accomplish

this:

a. Obtain the design airflow rate and the design external

static pressure drop through the distribution system. Your

sales representative or the design engineer can provide

you with these values.

b. Using the table from the Service Facts, add the static

pressure drop of the accessories installed on the unit.

c. Add the total accessory static pressure drop (from step

1b) to the design external static pressure. The sum of

these two values is the total system external static

pressure.

2. Use the table(s) in the Service Facts to find the external

static pressure Pa (inches of water column) that most

closely approximates total system external static pressure.

Then locate the appropriate airflow rate (in m3/h) for your

unit. The value obtained represents the kW for the evapora-

tor fan motor and the fan RPM.

Summary of Contents for YK-IOM-2

Page 10: ...10 Figure 5 Figure 6 Detail of the Gas Section...

Page 17: ...17 Figure 11A Zone Sensor Interconnections...

Page 18: ...18 Figure 11B Conventional Thermostat Interconnections...

Page 23: ...23...

Page 24: ...24...