17/30

4.5 Ducted

Heaters

4.5.1

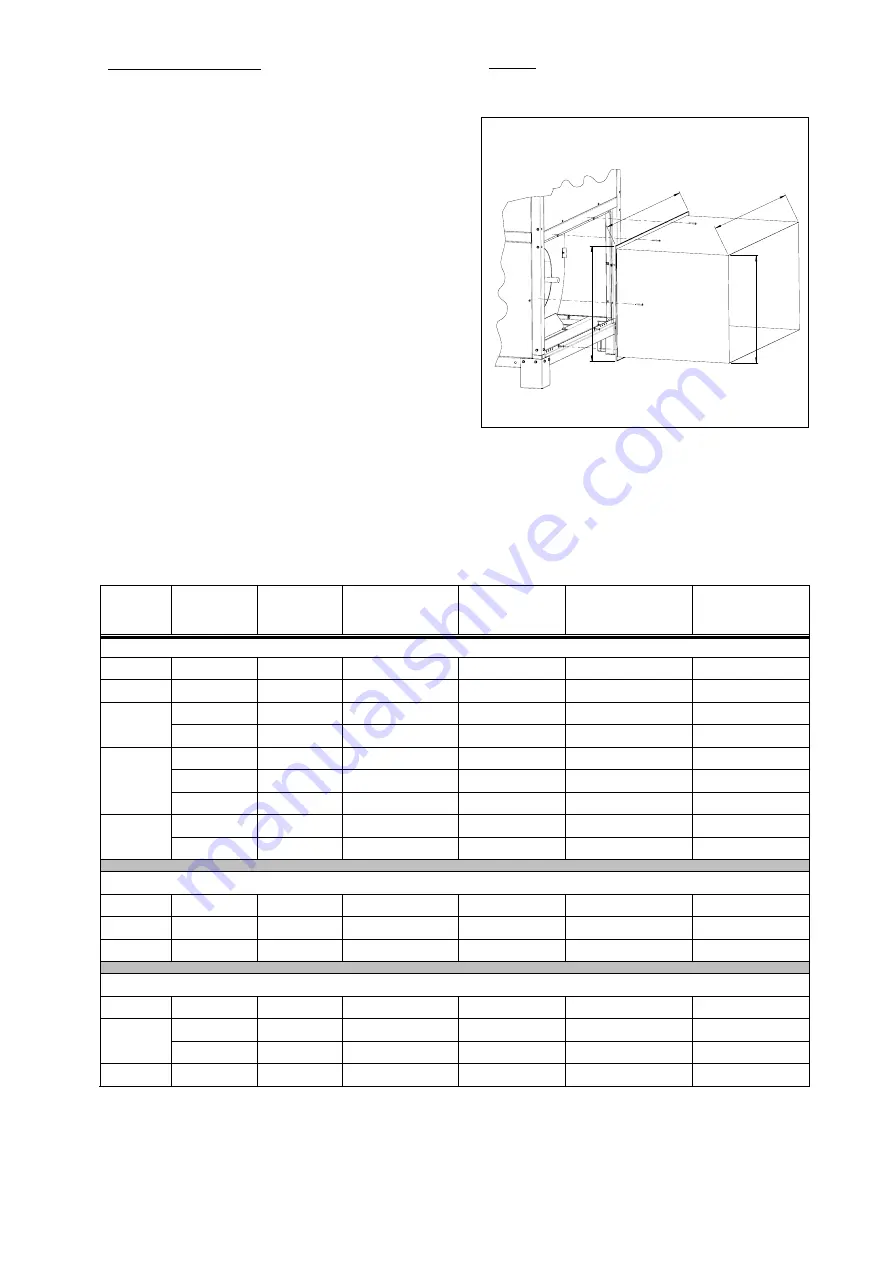

The Ambi-Rad ducted cabinet heater is

designed to be used with discharge ducting.

A positive seal should be made between

any ducting and the air heater. A flexible

connection is desirable to eliminate

transmission of noise and to take account of

thermal expansion.

4.5.2 Consideration

should be given to the

application of duct fittings directly connected

to the appliance. Air outlet elbows,

transitions etc. should be designed to ensure

an unrestricted and turbulent free air flow.

This requirement is to ensure than an even

air temperature is maintained when leaving

the appliance thus eliminating heat

exchanger "hot-spots" and nuisance shut-

down of the burner due to over heating.

4.5.3

Figures 8 and. 10

illustrate the principle and

the method of fixing duct channels to the

heater

-

ducts must have adequate duct flanges to

fit into the frame structure of the heater

-

the dimensions DA1/DA2/DA3/DA4 refer to

the duct flange; the dimensions

DB1/DB2/DB3/DB4 refer to the duct.

-

duct flanges must be screwed to the frame

structure; holes are provided in the frame

Remark

: fig. 10 shows ducted air inlet fixation – same

fixation method applies for ducted air outlet

Figure 10

DB

4

DB3

DA

4

DA3

Attention must be given to the motor load when

applying discharge ducting. Duct outlets must be

adjusted when necessary to meet the values mentioned

in table 9.

Table 9

Frame Model Nominal

airflow

Available outlet

static pressure

Motor load

(maximum)

Motor current

normal use (*)

Voltage

m³/h Pa

(A)

(A)

(V)

Standard airflow conditions

I

30/40

2500

95

4.00

3.4

230V – 1N

II

50/60/75

5180

130

9.00

7.8

230V – 1N

90

7140

125

3.20

2.3

400V – 3N

III

120

8750

150

5.08

3.7

400V – 3N

140

10500

200

6.60

5.4

400V – 3N

150

11500

215

8.00

7.8

400V – 3N

IV

180

12800

250

8.50

8.4

400V – 3N

215

14100

160

9.00

7.0

400V – 3N

V

250 17330

250 11.50

11.0

400V – 3N

High airflow conditions (when option 403 is applied)

Frame III

90

8750

150

5.08

3.7

400V – 3N

Frame IV 140/150

12800

250

8.50

8.4

400V – 3N

Frame V

215

17330

230

11.50

11.0

400V – 3N

High outlet static pressure conditions (when option 404 is applied)

Frame III

90

7140

205

5.08

3.7

400V – 3N

140

10500

350

8.50

8.4

400V – 3N

Frame IV

150

11500

310

8.50

8.4

400V – 3N

Frame V

215

14100

330

11.50

11.0

400V – 3N

(*)

Current is measured in cold air conditions (heating off) while unit is working at standard air flow. However, measuring motor

current of 10% lower than the figures mentioned in table 9, means that the air flow will be lower and the

∆

T higher. In this case

overheating can occur. To avoid this problem, larger outlets must be provided. In case motor current is greater than the

maximum motor load (mentioned in table 9) duct outlet openings must be decreased so that motor load becomes lower.

We strongly recommend respecting the figures given in table 9.