A–14

16023463

©2006 Maytag Services

Care and Cleaning

(cont’d)

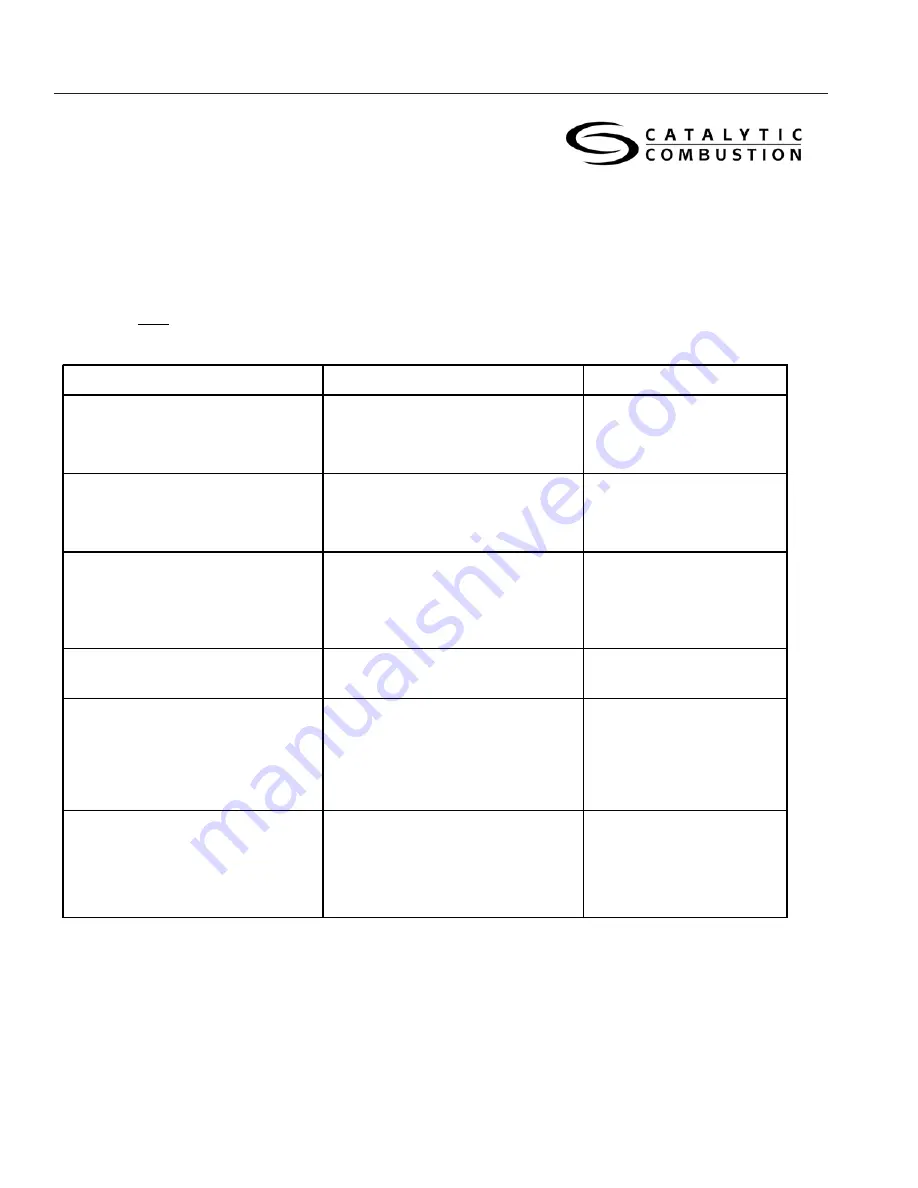

CATALYST DEACTIVATION & POISONING AGENTS

The following partial list of poisoning agents and inhibitors have been found to have a detrimental effect on the

activity of the noble metal catalyst. Optimum life and performance of the catalyst requires that exposure to these

substances must be avoided.

SUBSTANCE

EFFECT

REMEDIAL ACTION

1.

Coating Agents

a. rust

b. dirt

c. inorganic oxides

Covers catalyst active site.

Non-phosphate detergent

washing usually effective for

removal.

2.

Coating Agents - "Glass" Forming

Materials

a. organic silicates (esters)

b. silicones

Covers catalyst active site.

Replacement usually

required. Non-phosphate

detergent washing may be

effective.

3.

Poisons

a. heavy metals (such as

mercury, lead, zinc, tin,

arsenic, antimony, etc.)

b. phosphorus.

Permanent catalyst deactivation

None, replace with new

catalyst.

4.

Sulfides

Permanent catalyst deactivation

None, replace with new

catalyst.

5.

Halogens

a. fluorine

b. chlorine

c. bromine

d. iodine

e. halogenated hydrocarbons

Low concentration exposure -

Occupies active site resulting in

inhibition of oxidation reaction. High

concentration exposure – Chemical

reaction with washcoat components to

resulting in permanent deactivation.

Activity usually returns if low

concentration source is

eliminated. High

concentration exposure will

require replacement with new

catalyst.

6.

Organic Droplets and Aerosols

a. Covers active site

b. Possible cause of catalyst hot spot

Thermal cleaning in clean air

at temperatures 200°F hotter

than normal operating point

or chemical washing with a

strong alkaline solution.