1-6

American-Lincoln Technology

ATS 46/53 Troubleshooting Guide

Preliminary inspection is recommended prior to troubleshooting ATS 46/53 Sweeper/Scrubber hydraulic

systems. The inspection should include the following: reservoir oil level, engine speed at high throttle, broom

patterns, obvious oil leaks and hose connections.

TROUBLESHOOTING TABLE

PROBLEM

PROBABLE CAUSE

REMEDY

Main broom slow or will

not turn

1. Dump door closed

2. Hopper switch damaged

3. Side broom or main broom obstructed

4. Low engine speed

5. Damaged auxiliary pump

6. Damaged flow divider cartridge

7. Damaged relief valve

8. Damaged solenoid valve

9. Damaged vacuum motor

10. Damaged scrum motor

11. Damaged main broom motor

1. Open dump door. (See "Dump Door

Drifting Closed")

2. Inspect hopper switch located on the

rear of the hopper for continuity and

adjustment. Adjust, repair or replace.

3. Remove obstruction.

4. Adjust engine governor to proper speed

setting

5. Measure the auxiliary pump output with

a flow meter at high throttle. If the output

flow is 0.5 GPM or below the normal

minimum operating flow, replace or

repair pump.

6. Measure side broom speed with a photo-

tach. If the speed is 10 rpm above the

maximum normal operating speed,

replace the cartridge.

7. Inspect main manifold relief cartridge

(RV1) O-rings for damage and replace

O-rings as required. Hold the dump door

lever in the open position and measure

the pressure at the auxiliary pump. The

gauge should read 2600 ± 100 PSI. If

the gauge reads less that 2400 PSI,

reset or replace the relief valve.

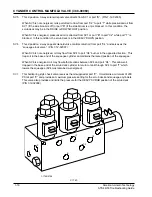

8. Inspect the solenoid valve (SV1) cartridge

O-rings in the main manifold for damage

and replace the O-rings as required. Also

inspect the cartridge for signs of

contamination and replaced as required.

9. Measure auxiliary pump pressure at the

pump with the main broom on and in

float. If the gauge reads above 2000 PSI

inspect the scrub motors for seizure

and repair or replace as required.

10.

11.

Measure auxiliary pump pressure at the

pump with the main broom on and in

normal scrub on. If the gauge reads

above 2000 PSI, inspect the scrub motor

for seizure and replace or repair.

Repair or replace motor.

Side broom slow

1. Damaged flow divider cartridge

2. Damaged solenoid valve

3. Damaged side broom motor

1. Measure the flow leaving the port "P1"

of the main manifold valve with a flow

meter. If the flow is below 0.65 gpm,

replace the cartridge (FR1).

2. Inspect the side broom solenoid valve

(SV1).cartridge O-rings in the cylinder

control manifold for damage and replace

the O-rings as required. Also inspect

the cartridge for signs of contamina-

tion and replace the cartridge as needed

3. Repair or replace the motor