MN-29758 (Rev. 6) 05/15 •

TH/III-SK/III Series Cook, Hold, Smoke •

25

eQUIpMent care

Under normal circumstances, this

oven should provide you with long

and trouble free service. There is no

preventative maintenance required,

however, the following Equipment Care Guide

will maximize the potential life and trouble free

operation of this oven.

The cleanliness and appearance of this equipment

will contribute considerably to operating efficiency

and savory, appetizing food. Good equipment that

is kept clean works better and lasts longer.

clean daIly

1. Disconnect unit from power

source, and let cool.

2. Remove all detachable items

such as wire shelves, side

racks, and drip pans. Clean

these items separately.

3. Wipe the interior metal surfaces

of the oven with a paper towel to

remove loose food debris.

4. Clean the interior metal surfaces of the cabinet

with a damp clean cloth or sponge and any good

commercial detergent.

note:

Avoid the use of abrasive cleaning

compounds, chloride based cleaners, or

cleaners containing quaternary salts. Never

use hydrochloric acid (muriatic acid) on

stainless steel.

5. Spray heavily soiled areas with a water soluble

degreaser and let stand for 10 minutes, then

remove soil with a plastic scouring pad.

6. Wipe control panel, door vents, door handles,

and door gaskets thoroughly since these areas

harbor food debris.

7. Rinse surfaces by wiping with sponge and clean

warm water.

8. Remove excess water with sponge and wipe dry

with a clean cloth or air dry. Leave doors open

until interior is completely dry. Replace side

racks and shelves.

9. Wipe door gaskets and control panel dry with a

clean, soft cloth.

10. Interior can be wiped with a sanitizing solution

after cleaning and rinsing. This solution must

be approved for use on stainless steel food

contact surfaces.

11. To help maintain the protective film coating

on polished stainless steel, clean the exterior

of the cabinet with a cleaner recommended

for stainless steel surfaces. Spray the cleaning

agent on a clean cloth and wipe with the grain

of the stainless steel.

12. Clean any glass with a window cleaner.

Always follow appropriate state or local health

(hygiene) regulations regarding all applicable

cleaning and sanitation requirements for equipment.

c a r e a n d c l e a n I n g

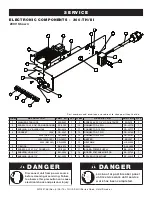

d a n g e r

Disconnect unit from power source

before cleaning or servicing. Failure

to observe this precaution can cause

electrical shock and personal injury.

d a n g e r

At no time should the interior or

exterior be steam cleaned, hosed

down, or flooded with water or

liquid solution of any kind. Do not

use water jet to clean.

Severe damage or electrical

hazard could result. Failure to

observe this precaution will void

the warranty.

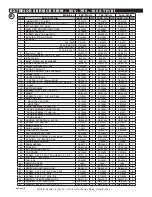

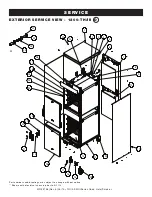

Summary of Contents for 1000-SK/III

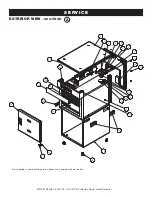

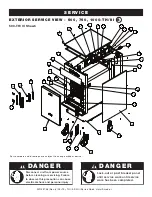

Page 47: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 45 ...

Page 48: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 46 ...

Page 49: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 47 ...

Page 50: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 48 ...

Page 51: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 49 ...

Page 52: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 50 ...

Page 53: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 51 ...

Page 54: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 52 ...

Page 55: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 53 ...

Page 56: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 54 ...

Page 57: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 55 ...

Page 58: ...MN 29758 Rev 6 05 15 TH III SK III Series Cook Hold Smoke 56 ...