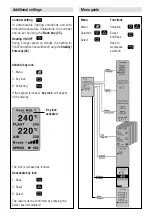

Monitoring the welding parameters

The actual and ideal values of the AIR and PLAST temperatures are constantly monitored. If an actual value deviates

from the relevant ideal value (value is outside the range of tolerance), this will be indicated by a change in status

on the

status display (30)

. If necessary, the drive motor will be temporarily disabled until the welding parameters

are back in the specified tolerance range. The possible status display and the ranges of tolerance are shown

in the following graphic and table.

No Status display

Status characteristics

Ready*

Ready to weld

M free

Divergence from welding parameters (plastic) > 10°C

Heating

Divergence from welding parameters (plastic) > – 30°C, drive motor disabled

30s

Start-up waiting period of 30 sec., drive motor disabled

Too hot

Divergence from welding parameters > + 30°C, drive motor disabled

Setting the output volume

The output volume and the pre-heating time can be coordinated with

each other according to the type of seam.

• Presetting on the display

– Move the cursor to the «SPEED» position by pressing the

Select key

(28)

.

– Specify the maximum output value (30-100 %) using the

Up (29)

or

Down (27)

keys (displayed on the

drive display bars (22)

).

• Precise adjustment during the welding process

– The output volume can be reduced from the maximum set value

(e.g. 85%) to the minimum by turning the

potentiometer (3)

.

The output volume is dependent on the size of filler rod used. If the output

is too large when the output display is set to «30» and the potentiometer

to «Minimum», the filler rod must be changed to the next size down.

Setting the PLAST and AIR temperatures

• Move the cursor to the «

PLAST

» or «

AIR

» position by

pressing the

Select key (28)

.

• Set the temperature value by using the

Up (29)

or

Down (27)

key.

3

22

Example

Welding preparation

24

27

28

29

30

31

17

18

19

20

21

22

23

25

26

Temperature display

Reference value

Actual value

Displayed state

Time

Motor

enabled

Motor

ena.

Motor

enabled

1

2

3

4

5