Summary of Contents for C 34

Page 2: ...2 ...

Page 27: ...27 ...

Page 42: ...42 ...

Page 43: ...43 C34 PARTS SECTION ...

Page 44: ...44 ...

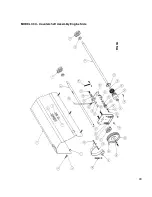

Page 49: ...49 MODEL C34 Countershaft Assembly Engine Side FIG 3A ...

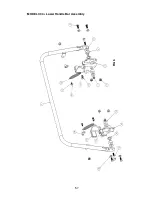

Page 51: ...51 MODEL C34 Counter Assembly Brake Side FIG 3B ...

Page 53: ...53 MODEL C34 Kickstand Assembly FIG 4 ...

Page 55: ...55 MODEL C34 Handle Bar Assembly FIG 5 ...

Page 57: ...57 MODEL C34 Lower Handle Bar Assembly FIG 6 ...

Page 59: ...59 MODEL C34 REAR ROLLER ASSEMBLY FIG 7 ...

Page 61: ...61 MODEL C34 Main Frame Assembly FIG 8 ...

Page 63: ...63 MODEL C34 BRUSH CARTRIDGE FIG 9 ...

Page 65: ...65 MODEL C34 VERTICUTTER CARTRIDGE FIG 10 ...

Page 67: ...67 MODEL C34 SCARIFIER CARTRIDGE FIG 11 ...

Page 69: ...69 MODEL C34 SORREL ROLLER CARTRIDGE FIG 12 ...

Page 71: ...71 MODEL C34 CUTTING CYLINDER 6 BL CARTRIDGE FIG 13 ...

Page 73: ...73 MODEL C34 CUTTING CYLINDER 6 BL CARTRIDGE FIG 14 ...

Page 74: ...74 Notes ...