Notch Filter

57

Important:

If the application requires high overload current for long durations

(e.g. 150% for 60 seconds), heavy duty sizing (between drive and

motor) will be required. See "Normal Duty and Heavy Duty

Operation" on

page 39

.

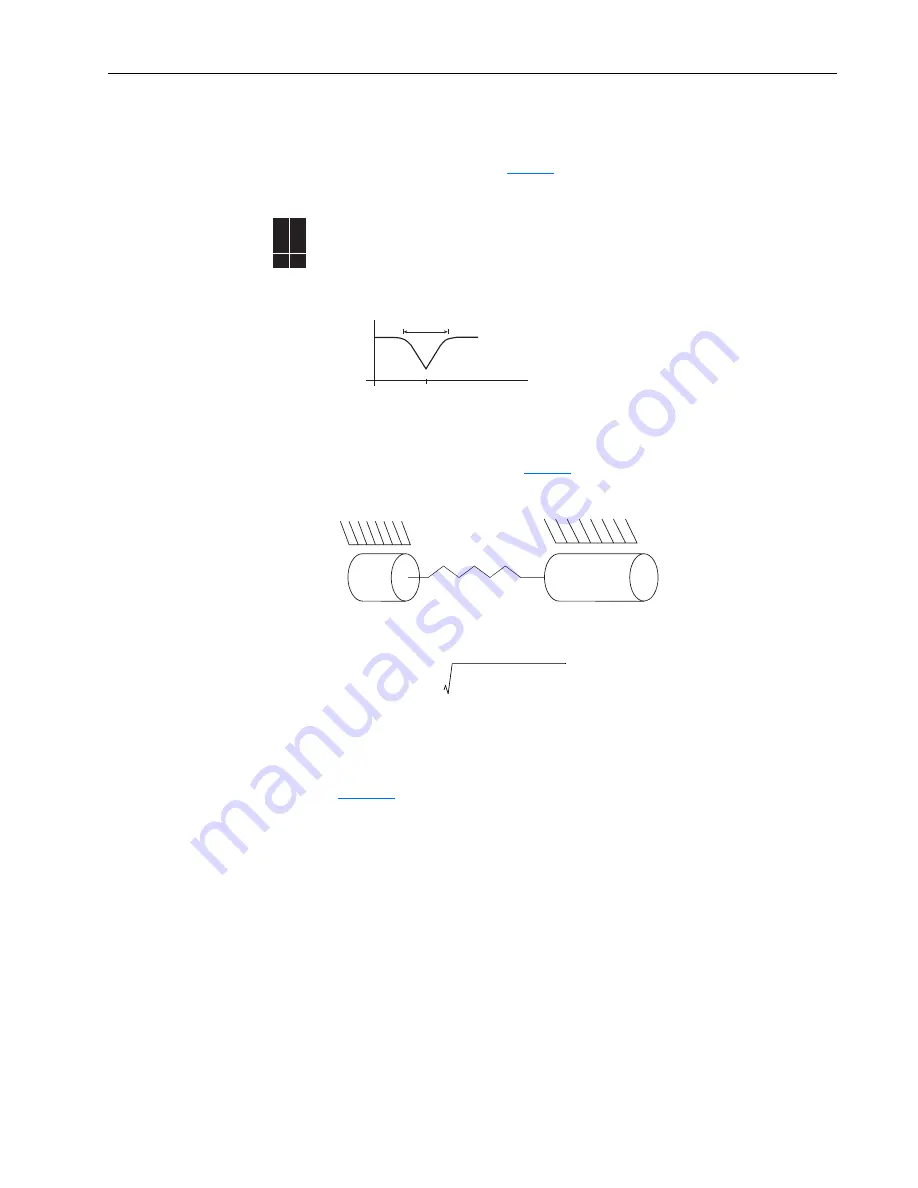

Notch Filter

A notch filter exists in the torque reference loop to reduce mechanical resonance

created by a gear train. [Notch Filter Freq] sets the center frequency for the 2 pole

notch filter, and [Notch Filter K] sets the gain.

Figure 9 Notch Filter Frequency

Example

A mechanical gear train consists of two masses (the motor and the load) and spring (mechanical

coupling between the two loads). See

Figure 10

.

Figure 10 Mechanical Gear Train

The resonant frequency is defined by the following equation:

Figure 11

shows a two mass system with a resonant frequency of 62 radians/second

(9.87 Hz). One Hertz is equal to 2

π

radians/second.

70EC

700VC

700H

✔

Gain

0 db

Hz

Notch Filter Frequency

Notch Filter K

Kspring

BL

Bm

Jm

Jload

Jm is the motor inertia (seconds)

Jload is the load inertia (seconds)

Kspring is the coupling spring constant (rad

2

/sec)

resonance

Kspring

Jm

Jload

+

(

)

Jm

Jload

×

-------------------------------

=