16

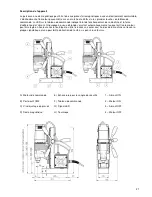

How to work with annular cutters

•

Push ejector pin (center pin) through head of annular cutter.

•

Core drills with Weldon shank are tightened with clamping screws (DIN 913) on both clamping surfaces.

•

First place annular cutter with ejector pin on a marked centre or marking.

•

Set the cutter and spot-drill, until the entire cut edge is formed as a circle.

•

During the drilling process, the cutter should be cooled permanently. Optimal cooling is possible by internal

cooling with our coolant unit.

•

During the drilling process, do not stop the motor. After the drilling process, draw back the cutter with running

motor.

•

Remove chips and core after each drilling.

Remove chips with chip-remover

.

Do not touch with bare hands

.

Danger of injury!

How to work with twist drills

•

The drill chuck with Weldon shank is only to be used with twist drills up to a diameter of 13 mm.

•

Insert drill chuck with MT2 tool holder in the drill spindle.

•

Insert twist drill in drill chuck and tighten.

Cleaning

Pull plug prior to cleaning. Danger of injury

by unintentional switching on.

•

Clean the outside of the motor by means of dry compressed air.

•

Check connecting lines on damages.

•

Clean and grease sliding surfaces regularly.

•

Carbon brushes should be replaced after appr. 250 hours running time.

•

After the work is finished we recommend to store the metal core drilling machine in the transport case in a

lying position.

Summary of Contents for ROTABEST RB50X

Page 43: ...43 Ersatzteile Spare Parts Pièces de rechange Piezas de recambio ...

Page 49: ...49 ...

Page 50: ...50 ...

Page 51: ...51 ...