10

EREctiOn And cOmmiSSiOning

• Carefully remove the packaging/unpack the device.

• Make sure that there is no damage. If damage is found, report it to the carrier immediately.

• The punching unit may only be used indoors.

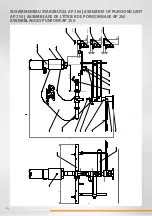

• Mount/securely attach the base plate of the punching unit to the workbench.

• Attach the swivel arms and secure with the grub screw.

• Insert the punching unit into the base plate and secure with the grub screw.

• Insert the length stop into the mount.

• Connect up the electro-hydraulic pump, changing the connection coupling if necessary.

• Switch on the red control switch on the electro-hydraulic pump.

• Insert the power bank and connect up the laser using the USB cable.

• Check that the light spot is present.

• Check the up and down motion of the pistons.

the feather keys on the punching unit for the fixation of the die support must not be damaged.

!

wORKing with thE Punching unit

1. Use the two grub screws to secure the die support to the punching unit (pre-mounted).

3 die supports are available for selection in accordance with the size of the tools. The fastening screws

must be tightened firmly (max. tightening torque MA of 50 Nm) and must be checked from time to time

to ensure that they are tight.

2. Insert the punch holder for round punches into the tool holder on the piston rod and secure with the

grub screw. Two punch holders are available.

3. Insert the mounting shaft of the round punch into the punch holder and secure with the grub screw.

- Screw the mating thread of the round punch onto the punch holder until it is hand tight.

- Insert the forming stamp directly into the tool holder with the torsion protection.

4. Insert the die into the die support.

5. Check the intersection between the punch and die by means of an idle stroke.

6. Place the neoprene scraper onto the punch holder.

7. Insert and position the workpiece. Swift and complete punching is required to ensure the reliable

ejection of the waste piece.

8. Once the punching process is complete, relieve the cylinder.

do not unnecessarily burden the neoprene scraper of the punch holder.

!

do not use blunt or damaged tools.

!

make sure that the punch and die are the correct size.

!

to ensure an optimum punching result and reduce wear on the tools, we recommend that you

regularly clean and rub the punches and dies with a cloth and conventional oil, particularly the

cutting edges.

Replace or resharpen the tools in good time.

!