8

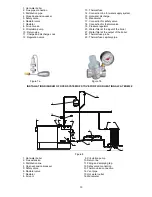

The device is of one piece with the thermal valve and valve for filling.

Valve opening temperature is 100°C (+0°C/-5°C).

The fluid recommended in the installation is water and glucose antifreeze of 30%.

Note:

At reaction, and valve operation, during fluid cooling in an overheated boiler part of the new fluid is injected into

the boiler, but the part is also ejected from the boiler. It will be poured down the drain. If the antifreeze is in the

installation you must keep in mind that a certain percentage will go out and pour down the drain!

We recommend the thermal valve Caleffi type 544, 1/2" as shown in Figure 7a.

6.2.2 SLOPE PRESSURE REGULATOR 1/2" WITH MANOMETER (Fig. 7, Item 19 and Fig. 7b)

When installing the thermal valve it is required to mount the slope pressure regulator as shown in Fig. 7, Item

19. The pressure that is maintained by pressure regulator must be set at a higher pressure than the pressure

that is in the heating system. If you do not have a higher water pressure of at least 0.8 bar compared to the

pressure in the heating system thermal valve will not work or cannot inject cold water into the boiler that needs

to be cooled.

Pressure regulator should be set to 2.8 to 3 bars.

You should take into account the direction of placing the slope pressure regulator

6.2.3 WATER FILTER OF THE BOILER INTAKE (Fig. 7, Item 20)

In front of the slope pressure regulator on water intake from water supply line it is necessary to install a filter

that will clean the water from solid objects, primarily of sand, which can damage the tap seal or seals of the

thermal valve and the slope pressure regulator.

This filter does not need to be resistant to high water temperatures due to cold water that flows through.

6.2.4 WATER FILTER OF THE BOILER OUTLET (Fig. 7, Item 21)

It is required to install the filter on the boiler outlet which will clean the hot - boiling water from dirt and solid

objects that can damage the tap seals, or seals of the thermal valve.

This filter must be resistant to water temperatures up to 15

0°C.

NOTES:

- After the completion of thermal valve activation, checking the pressure in the installation and filling the system

with cold water is mandatory.

- In cases where antifreeze is used, after filling the installation with water it is required to check percentage

content of antifreeze in a mixture of water and antifreeze!

- To avoid elimination of the antifreeze agent solution from the installation, it is best to have backup battery

supply of the pump with an inverter.

6.3 SAFETY VALVE (fig. 7 and 8 pos. 5 and fig. 4 pos. 6 )

On the back side of the boiler under the hob, a connection R1/2" is welded (fig.4 pos.6) in which you are

OBLIGED to set a safety valve. The safety valve should be between 2,5 to 3 bar. It can be installed directly on

the terminal or at a distance from the stove of 1m the most, provided that there is no block valve between the

boiler and the safety valve.

In an open heating system, the safety valve is not put normally, but we advise that you put it as one more type

of insurance of the boiler and the system (due to unforeseen circumstances).

WARNING:

If the safety valve is not set as previously explained, the guarantee ceases.

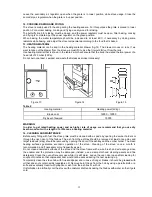

6.4 THERMOMETER AND MANOMETER (fig. 1 pos. 16 and 17 and fig. 5)

On the stove itself, on the additional cover (fig.1 pos.24) between the firebox door and the ashtray door,

thermometer and manometer are mounted (fig.1 pos.16 and pos.17, and fig.5) so they do not have to be

placed on the installation.

The thermometer pos. 17 shows the temperature of water in the boiler (operating temperature) in

°C.

The manometer pos. 16 shows the water pressure in the boiler, that is, in the system, in bars.