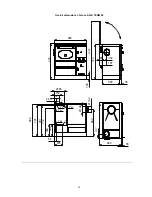

12

The firebox can be filled from the upper side as well (fig.12). The cover is lifted by using a wrench and

firewood is put. It is not recommended to put some organic waste in the stove (plastic bags, bones etc.)

because in this case tar collects on the walls of the flue channel and this can cause a fire.

After every filling it is recommended that the stove burns with maximum power for at least half an hour since

in the beginning all volatile compounds in the fuel burn, which are actually the main causes for condensate

creation in the stove.

Insert the coal when there is good (strong) ember in the firebox, two to three times at intervals of 15 minutes.

Figure 12

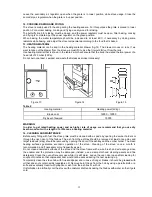

9. GRATE USE IN UPPER AND LOWER POSITION

For cooking, baking and frying in the transit period, the upper grate position is used (fig.11) so that the flame

could directly reach the hob thus saving the costs for cooking, baking and heating.

The stove is delivered with a grate in lower position. In order to move the grate from the lower to the upper

position, it is necessary to do the following:

- Remove the hob from the stove and open the door of the firebox and the ashtray.

- The grate should be pushed completely back with a rod for shaking the grate and then through an opening

of the ashtray door and the space for ash and the front part of the grate should be lifted by hand and should

be pulled out from its bearing (position). After this, the carrier of the grate is lifted and pulled out.

- The placement of the grate in upper position is performed in reverse order. The grate carrier is placed on

the grate holders (pieces 4) welded in the boiler firebox in front and on the back side (pieces 2+2) (fig.1

pos.23). In the grate carrier bearing insert the grate under an angle (aslant) so that the back part of the grate

enters first and then put down the front part of the grate. Move the grate forward and backward so that it lies

well in the grate carrier bearing. Put the hob in the carrier bearing of the hob frame.

- Placement of the grate in lower position (fig.9 and 10) is performed in the same manner as the upper

position, provided that in the end the front part of the grate is lifted a little and through the rectangular opening

of the rod carrier (fig.1 post.25) the rod for shaking the grate should be inserted. The grate is slowly put down

so that the grate notch falls in the opening of the rod for shaking the grate.

Warning:

- In the lower grate position, the heating of water is better, larger number of radiators can be heated and

bigger surface of living space, but cooking is more difficult.

- In the upper grate position, the heating of water is weaker, small number of radiators can be heated and

small surface of living space, but cooking is much easier.

- In both grate positions baking is the same (it is not impeded).

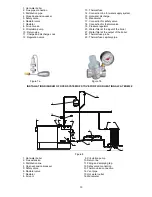

10. AUTOMATIC REGULATION

The stove power is adjusted with a thermostat (power regulator, combustion regulator) located in the ashtray

door and which automatically adjusts the lapse of the regulator flap depending on the adjustment of the

regulating knob (fig.1 pos.10 and pos.19) and the height of water temperature in the stove heater. The

regulation knob has many positions written on the knob and this is shown in table 1 as follows:

Table 1

Position of regulator knob

0

3

4

5

7

9

Water temperature in the stove (

C)

Closed regulator

30

40

50

70

90

The cover (flap) for air in the power regulator system completely regulates the air intake for combustion it he

remaining openings are closed.

11. SECUNDARY AIR REGULATOR

A secondary air regulator is placed in the firebox door (fig.1 pos.8 and fig.13). It is used for regulating the

subsequent ignition and combustion of unburned gases. Its opening and closing is performed manually

through a knob positioned on the firebox door.