3

DEAR BUYERS!

Thank You for the trust you showed us buying our stove for floor heating. We assure You that You have

chosen a quality and economic product that is a result of many years of experience of this factory in the

production of stoves and furnaces for floor heating.

We hope that we fully met Your requirements in terms of design, as well as in terms of the surface of living

area that you can heat.

Please carefully read these instructions before connecting the stove and adhere to every advice provided

herein.

1. PURPOSE

The continually burning stove for floor heating with solid fuel is used for:

-

cooking,

-

baking,

-

heating apartments, individual houses and offices,

-

production of hot sanitary water.

It is mostly installed as a stove for floor heating, and it can also be installed for central heating.

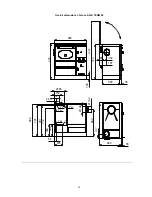

2. APPEARANCE AND STRUCTURE OF A STOVE WITH A FLOOR HEATING BOILER (fig.1)

1. Stove cover

2. Cooking panel (hob)

3. Cooking panel extension

4. Butterfly knob for opening and closing

5. Oven door (oven)

6. Oven thermometer

7. Firebox door

8. Secondary air regulator knob

9. Ashtray door

10. Thermostat knob (combustion regulator)

11. Rod for shaking ash

12. Ashtray (ash box)

13. Ember holder

3. SAFETY AND RELIABILITY IN STOVE OPERATION

The stove for floor heating is constructed so that it enables maximum safety during operation.

Safety during stove operation is provided in three ways:

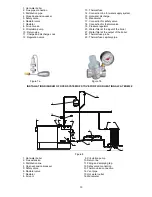

- combustion regulator (thermostat) (fig. 1 pos.10), located in the ashtray door, which automatically closes the

air intake in the stove firebox when the set water temperature in the boiler is reached,

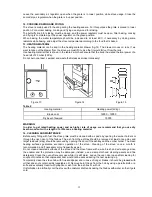

-Thermal valve (thermal fuse) (Fig. 7, Item 13 and Fig. 7a) when installed in the heating system serves as a

thermal fuse if the stove becomes overheated,

- safety valve (Fig. 7 and 8, Item 5) which MUST be installed on an R1/2" connection (Fig. 4, Item 4.)

NOTE:

Thermal valve and safety valve are not delivered with stove, while the thermostat is installed on the

stove's ash pan door.

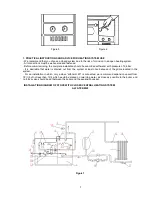

4. STOVE PLACEMENT (INSTALLING)

- The stove may be installed in the kitchen part or at some other convenient spot.

- An inflammable pad should be put under the stove.

- If the pad is flammable (wood, plastic), place a tin plate that should protrude from the lateral sides with 10cm

and 50cm from the front side.

- The furniture and objects located in front of or close to the stove must not be from flammable material. If they

are from flammable material, then the minimal distance from the stove must be 20cm.

14. Draving for wood

15. Cover for cleaning

16. Manometer

17. Thermometer

18. Hob cover

19. Thermostat flap

20. Flue extension

21. Cover of opening for cleaning

22. Handrail

23. Grate carrier

24. Additional cover

25. Rod bracke