6 Maintenance

Maintain the tank cleaning machine with care.

Read the instructions carefully and pay special attention to the warnings!

Always keep minor spare parts kit in stock.

6.1

General maintenance

Step 1

!

Always read the technical data thoroughly, see section 7 Technical data.

Recommended spare parts: Order service kits from the service kits list, see section 8 Parts list and service kits

Ordering spare parts: Contact your local Alfa Laval sales company.

6.2

General dismantling set up

NOTE

A rigorously implemented preventative maintenance program will significantly reduce repair costs over the life of the Alfa Laval

GJ.The foundation of such a program is regularly scheduled inspections to discover and replace worn or damaged parts before

they can cause the failure of other, more costly, components. The inspection intervals required will depend on the severity of the

application, but a complete internal inspection at 100 hours of operation is recommended initially.

Step 1

STORAGE

The Alfa Laval GJ should be washed out with clean water after

each use to remove any foreign material or soft substances left in

the machine that may harden during storage and cause the Alfa

Laval GJ to seize or lock up. A clean water rinse through the Alfa

Laval GJ will also wash out any residues of chemical cleaners or

recirculated wash water that could adversely affect the seals and

O-rings during prolonged contact in storage. The best position to

store the Alfa Laval GJ is to stand it up with the inlet connection

facing down.

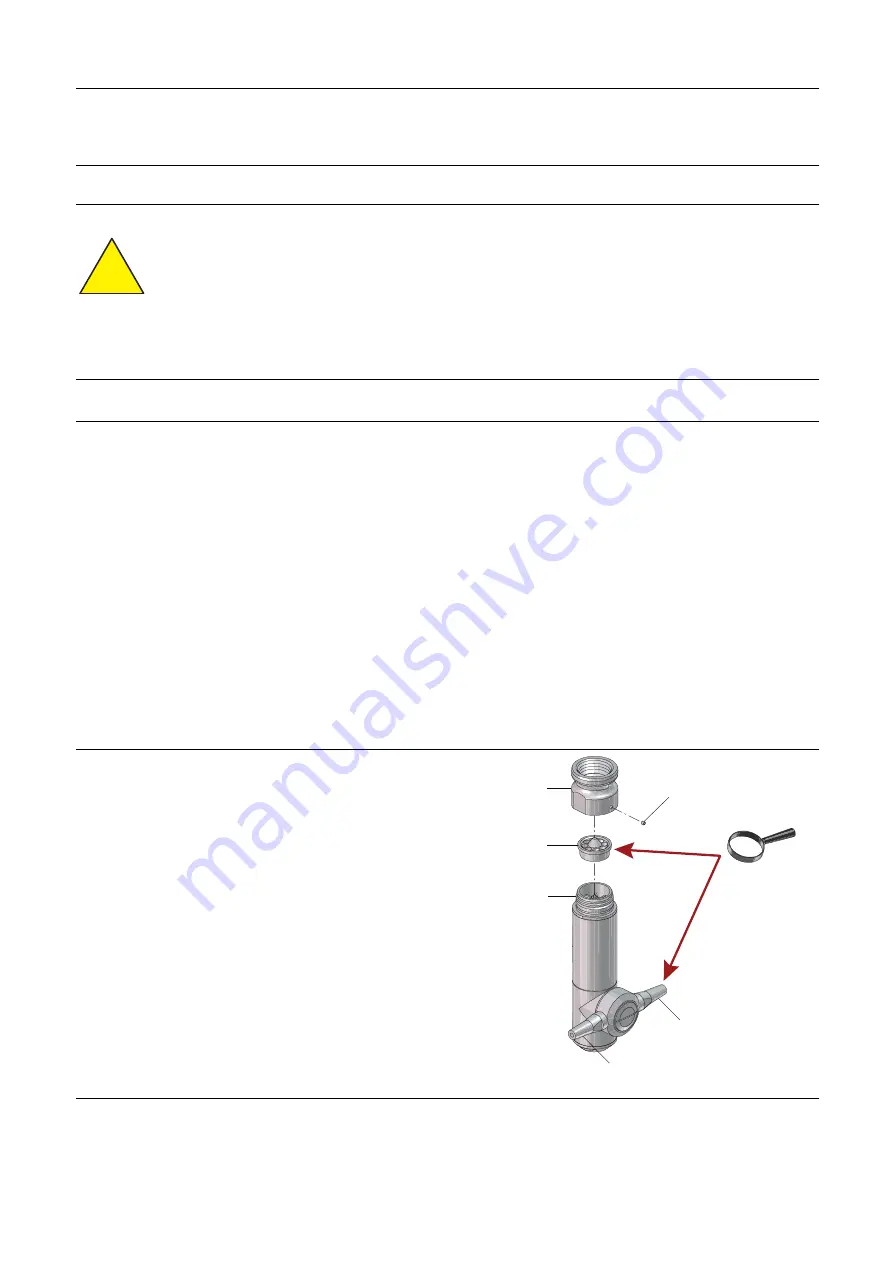

Step 2

EXTERNAL INSPECTION INTERVALS

Before every shift, the stator (12) and the nozzles (16) should be

inspected for debris. Examine the stator (12) by loosening the

collar set screw (30), while holding on the flats of the cap (6) and

remove the main section of the machine from the collar (11). Look

into each nozzle for signs of debris or build-up

12

30

11

4125-0010

16

16

6

21

Summary of Contents for GJ PF

Page 2: ......

Page 43: ... 43 ...