4 Operation

Study the instructions carefully and pay special attention to warnings! Always check the Agitator before operation. Alfa Laval

recommends a soft starter for the Agitator to reduce the load on tank and Agitator.

All position numbers and item numbers refer to the drawings shown and specified in chapter 7 Parts list/Service kits.

4.1

General information

!

Rotation of Agitator must always be clockwise.

Use of gear motor covers is not permitted due to risk of reduced cooling on motor.

If batch rotation is observed during operation, the optimum effect of the Agitator is achieved by interval agitation instead. If

interval agitation is used, the gear motor must be installed with a soft-starter or a frequency converter to increase gear motor life

time and reduce forces on the tank top system.

If a sensitive product is processed, agitation speed and time should be reduced as much as possible.

If the Agitator is equipped with an aeration valve, it is possible to aerate the product through the shaft during the agitation.

4.2

Aeration

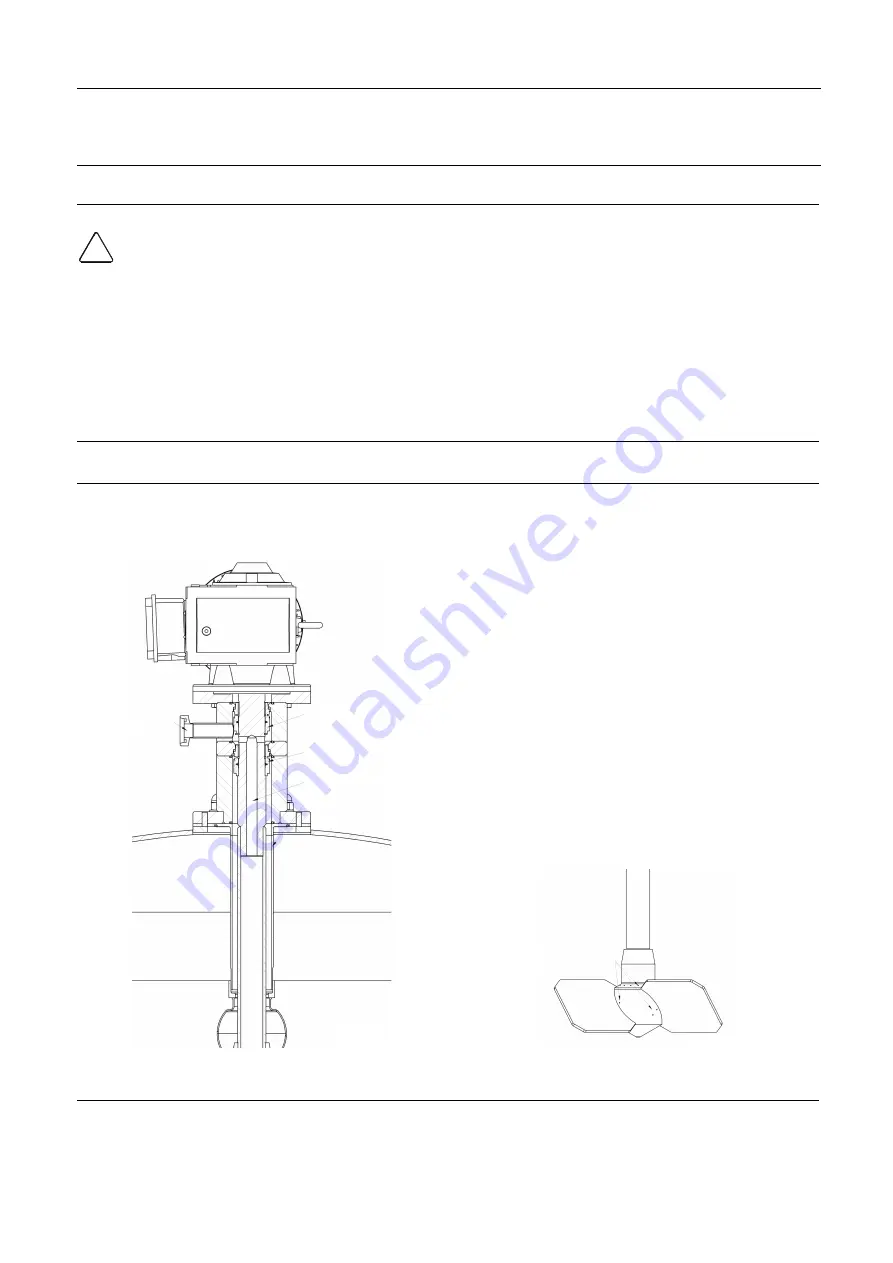

If Agitator is equipped with Aeration feature the upper connection (28) can be used letting in sterile air into the batch through the

inside of the shafts and out at the lower propeller. The flow versus pressure can be calculated from the formula described in

chapter 6 Technical Data.

A: Sterile air

B :Mechanical seal

C: Mechanical seal

D: Hollow shaft for aeration

E: CIP pipe

A

B

C

D

E

4304-0013

a: Nozzles for aeration and CIP

4304-0014

a

16