Page 20

Transducer Calibration should only be performed by an operator with the necessary calibration wheels or arm and weight

sets or by a calibration lab. Mountz offers calibration services to perform this function.

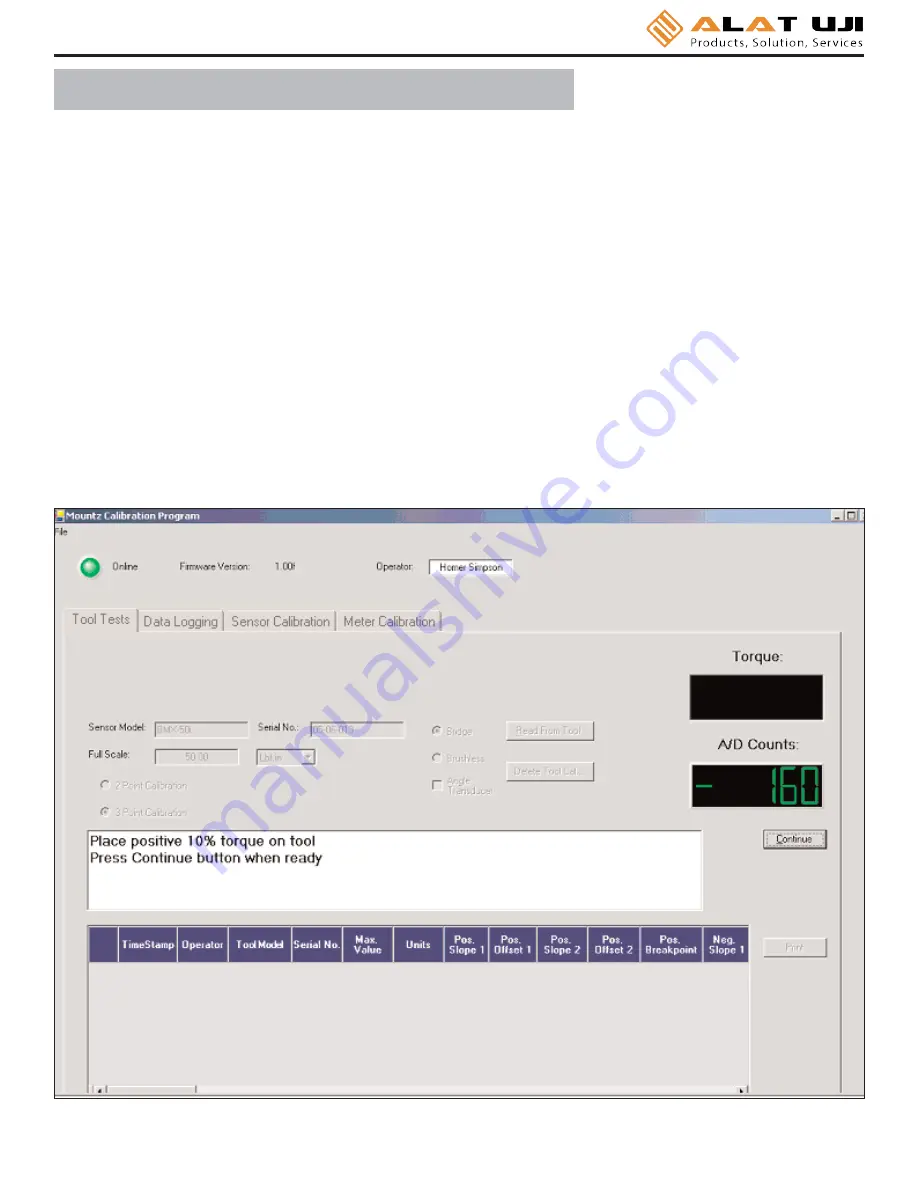

PTT calibrations are done in conjunction with a PC Windows based Calibration Program. The program is easy to use

and guides the user through the calibration steps.

Once the program is started and connected to the PTT meter, a button

"Start"

is provided to start the calibration. All the

needed information must be entered in the appropriate text boxes. This includes information such as the Sensor Model,

Serial Number, the Full Scale torque value, the units of calibration and the transducer type (Bridge or Brushless). Once

all required information is entered, the Start button is clicked, and its function changes to "Continue" as shown in figure

below and procedural information will be given in the large text box. A 2-point calibration should work well in all but

exceptional circumstances.

Once the calibration is complete the calibration data will be stored in a Mountz "Smart" transducer using the ARCII proto-

col. For non-smart transducers calibration data will be stored in the PTT internal memory. A sophisticated error

correction algorithm assures that the data written to and retrieved from memory is always correct.

Once the calibration is complete, Torque Values will be displayed in the Torque Window allowing for verification of cali-

bration data points.

T r a n s d u c e r C a l i b r a t i o n