1569H042 Ed.03

7

4.- Recommendations

Disconnect the voltage before carrying out any operations inside the electrical panel. All wiring should be according to

current standards and should be carried out by authorised staff. Only carry out the wiring foreseen in the wiring

diagrams. Using the electrical panel not observing the manufacturer's instructions may alter the appliance's safety

requirements. A tool is needed to remove any fixed part.

Panel installation:

It is advisable to leave a clean safety space without obstacles around the panel.

Do not knock or make sudden movements on the panel.

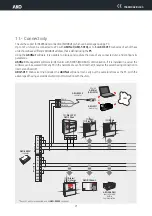

Carry out the wiring according to the installation manual.

The probes and their cables should

NEVER

be installed in a conduit together with power, control or feeder cables.

The earth terminals that the panels contain are installed to guarantee the continuity of earthing, however, earthing is

not carried out by the terminal and should be carried out outside the panel.

The neutral ratings are of the TT type. The IT rating should not be used.

Circuit breakers (protective switches) are of the phase/s + neutral, curve C type, guaranteeing switching and protection

against overcurrents.

Close the panel when your are not working on it.

Residual current protection outside the electrical panel according to low voltage electrotechnical regulations.

The panels meet European standard EN 61439-1 / EN 61439-2.

Terminals for copper external conductors.

Checks before starting the panel up:

Power supply voltages and frequencies will be the ones that figure in the "Technical specifications" section.

Check that there are no loose parts or foreign bodies on connections or switchgear.

Check that there is no dust or damp inside the panel.

Check the correct fastening of the switchgear and components.

Check the correct tightening of the screws and power connections.

Check the correct connection of the power conductors.

Check the correct insulation of the outer lines and that they do not mechanically force the inner connections of the panel.

Check that the maximum current of the Q1 and Q3 current breaker (according to model) has been set correctly.

Before starting the installation up, we recommend preheating the compressor's housing.

Checks during the panel start-up:

Check that no electric arcs occur.

Check that the relays or contactors do not produce ratios.

Check that there is no overheating in cables, controllers and the rest of the switchgear.

Checks after the first 24 hours of operation:

Check that no overheating occurs.

Retighten screws and power connections.

Periodical preventive maintenance:

The panel should remain closed using its lock.

Retighten the power connections once a year.

Check the wear of the switchgear once a year.

Clean the outer surface of the panel with a soft cloth, water and detergent. Do not use abrasive detergents, petrol,

white spirits or solvents.

Technical data:

Working ambient temperature: –5 ºC to 40 ºC

Rated isolation voltage Ui = 440 V~

Electrical panels with degree of protection: IP 65

CEM B environment

Terminals for copper conductors

Resistance to short-circuits Icc=6 kA

Rated pulse voltage (Vimp) 2,5 KV

Cable isolation voltage:

Operation: 500V (Halogen free)

Power: 750V (Halogen free)