40

EXPERT PN110 rev.23

EXPERT PN110

14. TRANSFER MENU

14.1. Screen Contrast

1. Simultaneously press and hold the up and

down

MENU SELECT

buttons for 5 seconds

to display the transfer menu.

2. Choose

7. Contrast

and press Enter.

3. Set the screen contrast to the desired

intensity then press Enter to validate.

4. Press and hold the up and down

MENU

SELECT

buttons for 5 seconds to exit from

the transfer menu.

14.2. Communication Speed

1. Simultaneously press and hold the right

and left arrow keys for 5 seconds to display

the system menu.

2. Choose

6. Comm Speed

and press Enter.

3. Set the communication speed to the

desired value: select the high speed mode

if the controller uses the A-BOX communi-

cation system or select the low speed if it

uses AGNET.

4. Simultaneously press and hold the right

and left arrow keys for 5 seconds to exit from

the system menu.

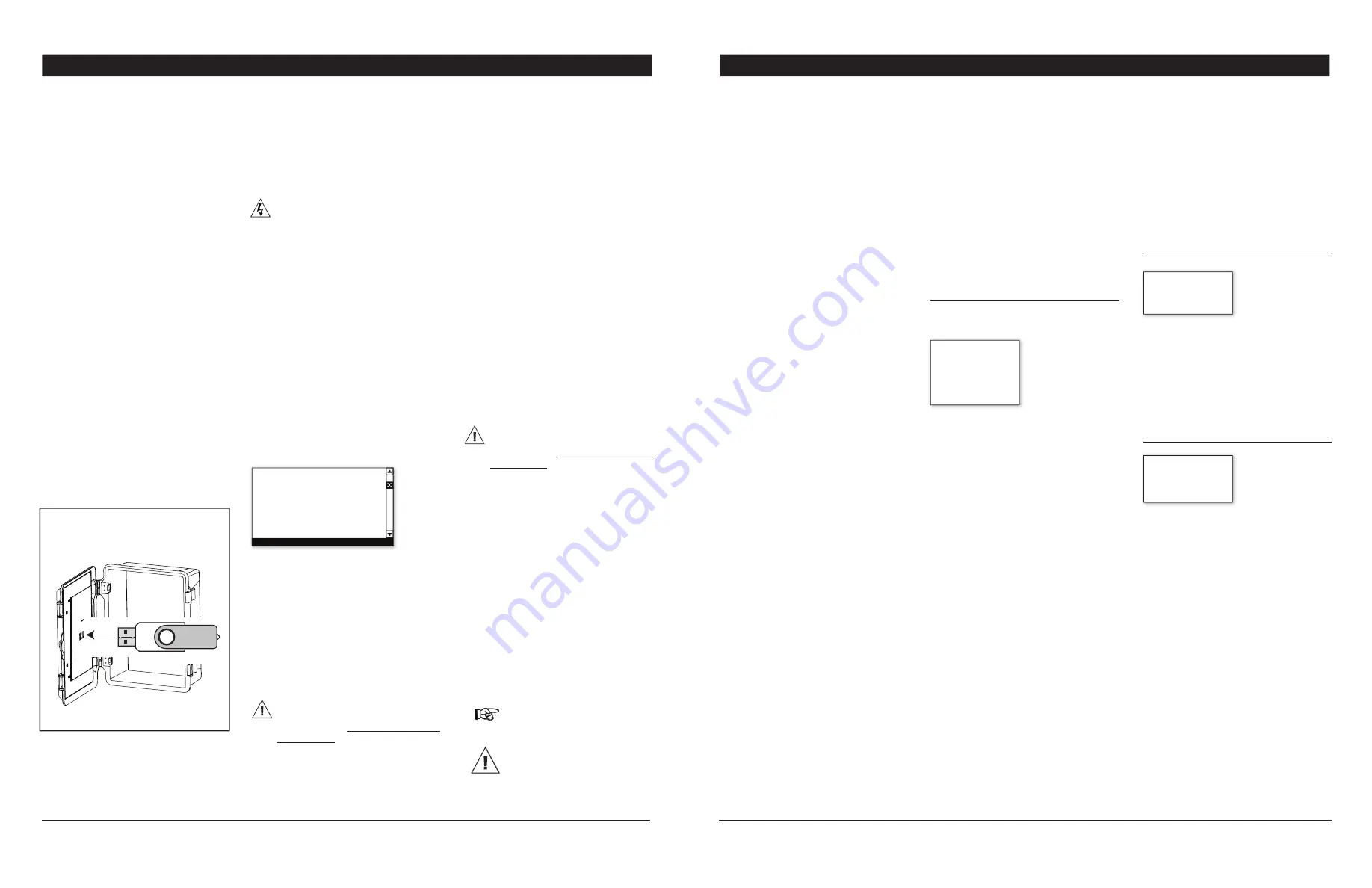

14.3. Update/Backup Process

The USB drive allows upgrading the

fi

rmware

or software of your controller. The USB drive

can also be used to make a backup of your

controller settings or to copy these settings

on another controller of the same type.

Turn off power each time you open the

controller’s enclosure. This prevents acci-

dental exposure to areas of high voltage.

1. Turn off power to the controller.

2. Lift the latches to open the front door of

the controller.

3. If a metal plate is located behind the front

cover, use a

fl

at head screwdriver to loosen

the two locks and lift it.

4. Insert the USB drive in the connector

behind the front door.

5. Close the front cover (or plate) and reap-

ply power to the controller.

6. Simultaneously press and hold the up and

down

MENU SELECT

buttons for 5 seconds

to display the transfer menu.

7. Select the desired option:

1. MemoryCard -> Control

2. Control -> MemoryCard

3. Update Firmware

4. Save Event Bu

ff

er

5. Save History Log

6. Comm Speed

7. Contrast

1. MemoryCard -> Control

Choose

1. MemoryCard -> Control

to load

a new con

fi

guration

fi

le into your controller.

This transfer will update your controller’s

software and parameter settings.

When selecting this option, a list of all con-

fi

guration

fi

les located on the card is displayed

(*.DMP

fi

les). Select the desired

fi

le and then

simultaneously press the ADJUSTMENT

up- and down-arrow keys to start the transfer.

Note that the controller can only read

the

fi

les that are located at the root of

the USB drive. It cannot access any

sub-directory!

2. Control -> MemoryCard

Choose

2. Control -> MemoryCard

to save

your controller settings on the USB drive.

The saving process will start as soon as you

enter this menu.

The controller will create a new CONTROL-

LER~1.DMP

fi

le at the root of the USB drive.

If this

fi

le name already exists, it will be saved

under a different name (“CONTROLLER~2.

DMP” for instance). This way, the controller

will never erase a

fi

le on the card.

3. Update Firmware

Choose

3. Update Firmware

to download a

new

fi

rmware

fi

le into your controller. This

process will not affect your parameter set-

tings.

When selecting this option, a list of all

fi

rmware

fi

les located on the USB drive is

displayed (*.PKG

fi

les). Select the desired

fi

le

and then simultaneously press the ADJUST-

MENT up- and down-arrow keys to start the

transfer

Note that the controller can only read

the

fi

les that are located at the root of

the USB drive. It cannot access any

sub-directory!

4. Save Event Buffer

Choose

4. Save Event Buffer

to save the event

buffer of the controller on your USB drive. The

fi

le will have a *.txt extension.

5. Save History Log

Choose

5. Save History Log

to save the hourly

reading of every probe input measured in the

past 190 days on your USB drive. The

fi

le will

have a *.CSV extension and will need to be

imported in Microsoft Excel.

To get instructions showing how to import

a CSV

fi

le in Microsoft Excel, type "

Import

CSV

fi

les in Excel"

in the Excel Help window

(Press

F1

).

Press and hold the up and down

MENU SELECT buttons for 5 seconds

to exit from the transfer menu.

Remove the USB drive from the

connector when the transfer is over!

USB drive

9

EXPERT PN110 rev.23

EXPERT PN110

brooder heater is on.

Allow purge? —

By default, the controller

automatically disables the curtain purge

when using the interlock function. Select

"Yes"

if you purge cycles to continue within

that mode.

Use Cooling? —

The controller can control

one cooling output. Select

“Yes”

to enable

this output.

Use Stir Fan? —

The controller can control

one stir fan output. Select

“Yes”

to enable

this output.

Use Soaking? —

The controller can control

one soaking output. Select

“Yes”

to enable

this output.

Variable-Speed Fan Minimum Speed —

Set

the absolute minimum fan speed of each

variable fan outputs (this speed does not

apply to the minimum ventilation cycles and

to stage 1). *

This parameter is accessible if the

variable outputs are enabled above.

Motor Curve —

The relationship between the

voltage supplied to a motor and its operating

speed is described by a motor curve. This

curve varies with the make and capacity of

the motor. The various motors available in the

industry have been divided into ten categories

and the controller has been programmed with

a different motor curve for each of these

categories. To ensure that the controller

supplies the correct voltages, an appropri-

ate curve must be selected according to the

type of fan motors used. The table at the

back of the installation guide enclosed with

your controller gives the motor curves used

by the different type of fans. Set this curve

separately for each variable output in use.

Use Outdoor Temperature Compensation on

Variable Stages 1 and 2 ?—

Select "Yes" to

use the outside temperature compensation

function to in

fl

uence the bandwidth of vari-

able fan outputs. *

This parameter is accessible

if the outside temperature sensor is enabled (see

sec. 4.7.1.)

Digit Display —

Select the information to be

displayed on the red LED display:

T° average

temperature

SP static

pressure

T°/SP

avg temperature & static pressure

T°/I1

avg temperature & inlet position

SP/I1

static pressure & inlet position

4.5. RH

Compensation

Setup

The controller offers different ways to com-

pensate for high and low relative humidity

(RH) levels in the barn. This section shows

how to enable the desired RH compensation

functions. Refer to chapter 9 of this manual

to get more information about each of these

compensation methods.

1. Select:

»

USER

»

5. RH Compensation*

* This menu is accessible if the humidity probe is

enabled (sec. 4.7.1).

RH Compensation

Minimum Vent ? Yes

Heater ? Yes

Mist Shutoff ? Yes

Curtain purge only

on Hi RH ? No

Mist on Lo %RH? Yes

2. Enable or disable the following relative

humidity (RH) compensation options:

Minimum Ventilation —

The controller can

compensate for high humidity levels by

increasing the minimum ventilation inten-

sity. Select

“Yes”

to use this compensation

method.

Heater —

The controller can compensate for

high humidity levels by activating heating

outputs in timer mode. Select

“Yes”

to use

this compensation method.

Curtain Purge on Hi RH? —

The curtain's

purge function can be enabled permanently

or it can exclusively be used when the RH

level is above the RH set point. Select

"Yes"

to use the purge function on high RH levels

only. *

Accessible if the Purge function is enabled in

the installation (see sec. 4.5). Refer to sec. 6.4.3 for

further information about this function.

Mist Shutoff —

The controller can deactivate

the misting output when humidity levels are

too high. Select

“Yes”

to use this compensa-

tion method.

Mist on Low % RH —

The controller can acti-

vate misting outputs when humidity levels are

too low. Select

“Yes”

to use this compensa-

tion method.

4.6. Probe

Setup

4.6.1. Probe Activation

Follow these steps to enable or disable the

probe inputs of the controller.

a) Temperature Probe Inputs:

1. Select:

»

USER

»

2. Temp Probes

Temp Probes Used

123456

2. Enable the desired temperature probe

inputs.

b) Other Probe Inputs:

1. Select:

»

USER

»

3. Other Probes

Probe Selection

Use RH? Yes

Use Water? Yes

Use Outdoor? Yes

Use Stat.Press? Yes

2. Enable the desired temperature probe

inputs amongst the probes that follow:

Use RH —

Select

“Yes”

if a humidity probe is

connected to the controller.

Use Water ? —

Select

“Yes”

if a water meter

is connected to the controller.

Use Outdoor? —

Select

“Yes”

if an outside

temperature probe is connected to the con-

troller.

Static pressure (SP) probe —

Select

“Yes”

if

a static pressure sensor is connected to the

controller.