En-18

8. 2. Vacuum process

CAUTION

Do not turn on the power unless all operations are complete.

If the system is not evacuated suf

fi

ciently, its performance will drop.

Be sure to evacuate the refrigerant system using a vacuum pump.

The refrigerant pressure may sometimes not rise when a closed valve is opened after

the system is evacuated using a vacuum pump. This is caused by the closure of the

refrigerant system of the outdoor unit by the electronic expansion valve. This will not

affect the operation of the unit.

Use a clean gauge manifold and charging hose that were designed speci

fi

cally for

use with R410A. Using the same vacuum equipment for different refrigerants may

damage the vacuum pump or the unit.

Do not purge the air with refrigerants, but use a vacuum pump to evacuate the system.

• If moisture might enter the piping, follow below. (i.e., if doing work during the rainy

season, if the actual work takes long enough that condensation may form on the

inside of the pipes, if rain might enter the pipes during work, etc.)

• After operating the vacuum pump for 2 hours, pressurize to 0.05 MPa (i.e., vacuum

breakdown) with nitrogen gas, then depressurize down to -100.7kPa (-755mmHg)

for an hour using the vacuum pump (vacuum process).

• If the pressure does not reach -100.7kPa (-755mmHg) even after depressurizing

for at least 2 hours, repeat the vacuum breakdown - vacuum process.

After vacuum process, maintain the vacuum for an hour and make sure the pressure

does not rise by monitoring with a vacuum gauge.

Evacuation procedure

(1) Remove the blank caps of the gas pipe and liquid pipe and check that the valves

are closed.

(2) Remove the charging port cap.

(3) Connect a vacuum pump and a pressure gauge to a charging hose and connect it

to the charging port.

(4) Activate the vacuum pump and vacuum the indoor unit and connection piping until

the pressure gauge becomes -100.7kPa (-755mmHg).

Evacuate from both the gas pipe and the liquid pipe.

(5) Continue

evacuating

the

system

for

1 hour after the pressure gauge reads

-100.7kPa (-755mmHg).

(6) Remove

the

charging

hose

and

reinstall the charging port cap.

8. 3. Additional charging

CAUTION

Do not turn on the power unless all operations are complete.

After evacuating the system, add refrigerant.

Do not charge the system with a refrigerant other than R410A.

Always keep to the limit on the total amount of refrigerant. Exceeding the limit on the

total amount of refrigerant will lead to malfunction during charging of refrigerant.

Do not reuse recovered refrigerant.

Use an electronic scale to measure the charging amount of refrigerant.

Adding more refrigerant than the speci

fi

ed amount will cause a malfunction.

Charge refrigerant using the liquid pipe.

Adding refrigerant through the gas pipe will cause a malfunction.

Add refrigerant by charging the system with the refrigerant in the liquid state. If the

refrigerant cylinder is equipped with a siphon, it is not necessary to place the cylinder

upright.

Check if the steel cylinder has a siphon installed or not before

fi

lling. (There is an

indication “with siphon for

fi

lling liquid” on the steel cylinder.)

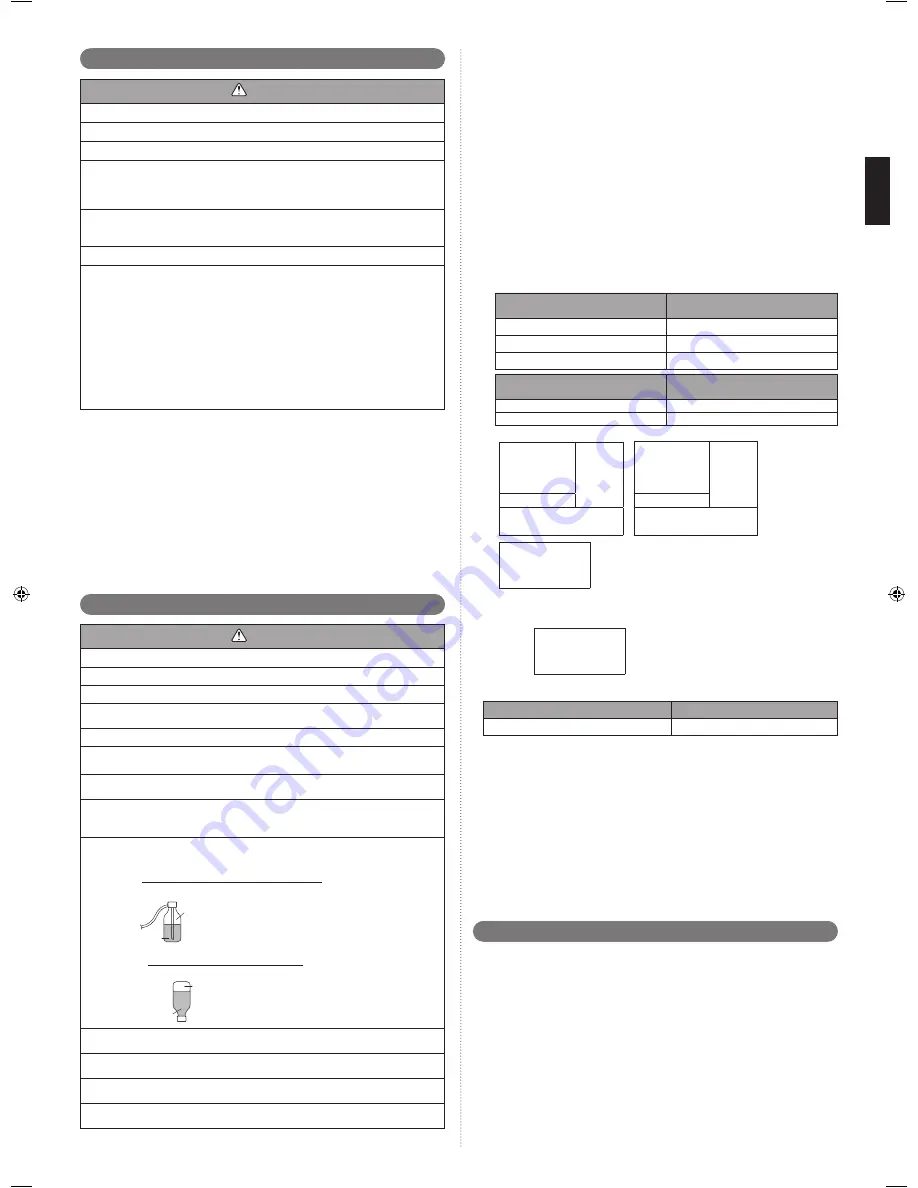

Filling method for cylinder with siphon

Set the cylinder vertical and

fi

ll with the

liquid.

(Liquid can be

fi

lled without turning bot-

tom up with the siphon inside.)

Liquid

Gas

R410A

Filling method for other cylinders

Turn bottom up and

fi

ll with liquid.

(Be careful to avoid turning over the

cylinder.)

Liquid

Gas

R410A

Be sure to use the special tools for R410A for pressure resistance and to avoid mixing

of impure substances.

If the units are further apart than the maximum pipe length, correct operation can not

be guaranteed.

Make sure to back closing valve after refrigerant charging. Otherwise, the compressor

may fail.

Minimize refrigerant release to the air. Excessive release is prohibited under the

Freon Collection and Destruction Law.

8. 3. 1. Procedure for charging the system with refrigerant

(1) Remove

the

charging

port

cap from the liquid pipe.

(2) Attach a charging hose to the refrigerant cylinder, and connect it to the charging port.

(3) Add

refrigerant

by

calculating

the

additional refrigerant volume in accordance with

the calculation formula indicated below.

(4) Remove

the

charging

hose

and install the charging port cap.

(5) Remove the blank caps (gas pipe and liquid pipe) and open the valves.

(6) Close

the

blank

caps.

(7) After adding refrigerant, indicate the added charging volume on the unit.

* Tighten the blank caps and charging port caps to the torque values speci

fi

ed in the

Table A.

To open and close the valves,

Use an M4 hexagon wrench.

8. 3. 2. Checking total amount of refrigerant and calculating

the amount of refrigerant charge to be added

• The amount of refrigerant charge to be added is the total value of the basic refriger-

ant charge amount and the value calculated from the length of the liquid pipe.

• Round up the value to 2 decimal places.

Model

B

Factory charged amount (kg)

AJY040LCLAH

4.0

AJY045LCLAH

4.0

AJY054LCLAH

4.0

Diameter of liquid pipe (mm)

a

Additional amount for pipe length (kg/m)

Ø6.35

0.021

Ø9.52

0.058

(1) Calculation of additional amount for pipe length

A =

Total length of

ø9.52 mm liquid

pipe

a

× 0.058

(kg/m)

m

kg

+

Total length of

ø6.35 mm liquid

pipe

a

× 0.021

(kg/m)

m

kg

=

Total

kg

(Round up A to 2 decimal place)

(2) Calculation

of

total

refrigerant

amount

C = A + B =

kg

(B : Factory charged amount)

Note: Check the total refrigerant amount under the following conditions

Condition

Computational formula

Total amount of refrigerant

C

≤

6.83kg

<Calculation>

Outdoor unit: AJY054LCLAH

(1) Calculation of additional amount for outdoor unit

If liquid pipe piping length is the following

Φ

9.52 : 20m ,

Φ

6.35 : 10m

Additional charge volume:

A = 20 (m) × 0.058 (kg/m) + 10 (m) × 0.021 (kg/m)

=

1.37

kg

(2) Check the total amount of refrigerant

C = A + B = 1.37 kg + 4.0 kg = 5.37 kg

≤

6.83 kg

→

No problem if the above condition is satis

fi

ed

8. 4. Installing insulation

• Install insulation material after conducting the “8.1 Sealing Test”.

• To

prevent

condensation

and

water

droplets,

install insulation material on the refriger-

ant pipe.

• Refer to the table to determine the thickness of the insulation material.

• If the outdoor unit is installed at a level that is higher than the indoor unit, the water that

has condensed in the 3-way valve of the outdoor unit could travel to the indoor unit.

Therefore, use putty in the space between the pipe and the insulation to prevent the

entry of water.

Table. Selection of insulation

(for using an insulation material with equal heat transmission rate or below 0.040W/(m·k))

9380545057_IM.indb 18

9380545057_IM.indb 18

2014/9/15 11:27:06

2014/9/15 11:27:06