9

UVHEALTH BIO2000 Installation Manual

5.2

UVHEALTH BIO2000 UNIT INSTALLATION

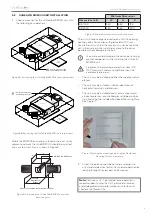

1. Choose a location for the UVHealth BIO2000 unit, with

the following considerations:

C:\Users\user\Mod Cons Heating & Cooling PTY LTD\Jobs - Documents\ZZZ DETAILS\FROM JIM'S PORTABLE HD\Do Not Amend - RCD CLEARANCE.dwg, Model

75mm clear zone around UV lamp

to prevent damage from UV light

Figure 8A: Positioning the UVHealth BIO2000 in the supply air duct

C:\Users\user\Mod Cons Heating & Cooling PTY LTD\Jobs - Documents\ZZZ DETAILS\FROM JIM'S PORTABLE HD\Do Not Amend - RCD CLEARANCE.dwg, Model

75mm clear zone around UV lamp

to prevent damage from UV light

Figure 8B: Positioning the UVHealth BIO2000 in a return air duct

Where the BIO2000 can not be installed in the duct unit or

adjacent ductwork, then the BIO2000 should be installed

into a custom transition, as shown in Figure 9.

Flex duct connection to suit required diameter

BIO1000 or BIO2000 unit

H

D

W

600x600

Maintenance

Access

Figure 9: Positioning the UVHealth BIO2000 in a custom

transition piece

Minimum Dimensions

Dimensions to fit

W

H

D

BIO1000

460

460

125

BIO2000

460

460

300

Figure 10: Minimum dimensions for transition piece

The unit will reduce organic build up on an HVAC cooling/

heating coil by illumination with germicidal UV-C rays.

Locate the unit such that the maximum surface area of the

coil is illuminated, while installing as close to the coil as

possible without damage to the coil.

Use care to avoid damage to the coil and any wiring

or other components while installing the UVHealth

BIO2000 unit.

To prevent water damage or electric shock, DO

NOT mount unit under a humidifier or near the

condensate drain pan.

•

The unit may be installed on either the supply or return

plenum.

•

The unit may be installed in upflow, downflow, or

horizontal flow ducts and plenums.

•

The unit may be installed directly onto a sheet metal

air duct or plenum, or onto fiberglass ductboard when

installed using the included Ductboard Mounting Plate.

See Figure 11.

Figure 11: Marking the mounting hole using the Ductboard

Mounting Plate as a template

2. Attach the quick connect power cord and plug in to

any standard electrical outlet. Verify lamp operation by

looking through the view port on front cover.

Note:

Continuous UV-C germicidal lamp operation is

recommended. Cycling the UV-C germicidal lamp on

and off degrades lamp performance much faster and

shortens the filament life.