12

UVHEALTH BIO2000 Installation Manual

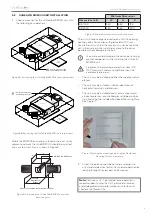

3. Detach the unit from the duct or Ductboard Adaptor

Plate by removing the four sheet metal screws. Save

the sheet metal screws for reattaching the unit.

Carefully slide unit out of duct.

4. Remove the lamp with the following steps. Disconnect

the ballast from the lamp by unplugging the four pin

connector (see Figure 7). Loosen lamp clip and slide

through the front end of the unit (see Figure 6). Be

careful not to break lamp.

5. Unscrew the end bracket by removing the hex screws.

Save the hex screws for reattaching the end bracket.

The end bracket is located on the opposite side of the

model to the power source. See Figure 14.

6. With the end bracket taken off, the honeycomb and

carbon media can be slid out of the opening in the back

of the unit. See Figure 15. The honeycomb panel and

the carbon media insert must be removed together

even if only one needs replacing.

Figure 14: Removing the end bracket hex screws

7. Replace any removed pieces of either honeycomb or

carbon media with the specified replacement parts

only. When sliding the replacement pieces back into

the unit, check and make sure the honeycomb is placed

on the inside while the carbon media is touching the

outside side panel.

8. Once the replacements are slid all the way into the

opening, attach the end bracket with previously

removed hex screws.

9. Carefully insert the lamp through the grommet on

the front end of the unit. Re-attach the lamp clip by

tightening down on the plastic end cap of the lamp. Re-

attach ballast by plugging connector into the four pins

of the lamp. Use a cotton cloth with isopropyl alcohol

and gently clean surface of lamp.

Figure 15: Removing the honeycomb and carbon media

10. Insert the unit back into duct opening and attach to duct

or Ductboard Mounting Plate using the four sheet metal

screws that were previously removed. The V shape of the

unit should face into the panel, see Figure 12. Replace

front electrical cover and plug the quick connect power

cord back into the unit.

11. Look through the round sight glass hole and verify the UV

lamp is lit. There should be a blue glow along the length.

If the lamp is not lit, follow the Troubleshooting guide.