3. Installation

3

-

5

M970010-1

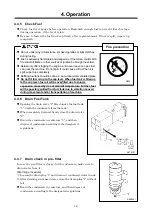

3.5

Compressed Air Service Valve

Do not fail to install a check at the outlet of compressed air

and then start piping.

If the piping is performed without a check valve

“

1

”

installed,

it is feared that the liquid in the piping can be returned into

the compressor air-end it can cause a damage to the

compressor air-end.

The check valve

“

1

”

should be in accordance with the

maximum working pressure of the compressor.

For safety operation, be sure to install a valve

“

2

”

before

the check valve

“

1

”

.

Further, for the parallel operation with other compressors,

the discharge of each compressor should be adjusted to

be the same level. Then perform the piping.

1

2

Compressor

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......