4.Operation

4

-

12

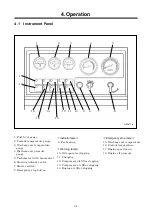

4.5 Unit Operation

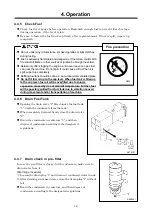

Operation with compressed air supply port opened is prohibited

Do not operate the machine with service valves and relief valve

open unless air hoses and/or pipes are connected.

High-pressurized air blows out and its air pressure could cause

injury to the people nearby.

When the machine has to be unavoidably temporarily operated

with its port open, be sure to mount a silencer to reduce noise

and wear protective materials such as earplugs to prevent

damage to hearing.

D003

4.5.1 Procedure to Start the Unit

Be sure to let unit warm-up after starting for smooth operation of the engine and the compressor.

Do not operate the engine at full load immediately after it starts up. This will shorten the equipment life.

During the warm-up operation, examine the different parts of the equipment for any looseness, leakage

of water, oil, fuel, and other irregularities.

Also, make sure that warning lamps are off.

(Procedure)

①

Close fully service valves

“

1

”

.

②

Set the starting unloader valve

“

2

”

to “START”

position.

③

Keeping pressing Stop button

“

3

”

, turn the

starter switch

“

4

”

to

“

START

”

position for

cranking operation. (Repeat cranking

operation 2 to 3 times about 4 to 5 seconds.)

④

Turn the starter switch to

“

GLOW

”

position

for preheating. (Time required for preheating:

about 20 to 40 seconds )

⑤

Immediately after finishing preheating, turn

the starter switch

“

4

”

to

“

START

”

position to

start engine.

⑥

Once the engine has started up, leave it

running to warm-up for 5 minutes. The

discharge air pressure in this condition ranges

from 0.39 to 0.49MPa.

⑦

After warm-up of the unit, put the starting

unloader switch

“

2

”

back to its “RUN” position,

and open the service valve The unit is now

ready to operate.

Be sure to turn the starting unloader valve

“

2

”

to “RUN” position prior to work. The discharge

pressure does not increase as long as the

starting unloader valve stays at “START”

position.

Adjustment of air delivery with the service valve

“

1

”

opened by halves can cause trouble. So

adjust air delivery with the

service valve “1” fully opened

.

Be sure to warm-up

3

1

2

RUN

START

TR0415-2

4 1

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......