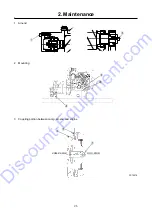

2. Maintenance

2-11

2.7

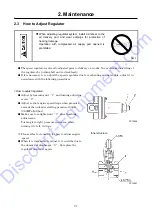

Change Oil Separator

●

When consumption of the oil is still unusual even after cleaning strainer in the scavenging orifice,

change the oil separator with a new one.

●

When replacing oil separator, be sure to replace gasket too.

<Procedure>

①

In order to pull out the oil separator

“

1

”

, unscrew the fixing bolts (M8, 4 pieces) for top cover

inspection cover provided on top of separator cover.

②

Remove the bracket for fixing the solenoid valve on the separator cover

“

2

”

and also remove all

the cables connected to the solenoid valve. Further, remove all the nylon tubes fixed on cable

connecting parts.

③

Remove the fixing bolts (M12, 4 pieces) provided at

flange of separator outlet.

④

Remove the fixing bolts (M12, 8 pieces) of separator cover

“

2

”

.

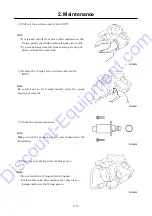

⑤

Screw two lifting eyebolts (M12) for the 2 threaded holes provided on the separator cover

“

2

”

.

⑥

Pass a rope through the eyes of the lifting bolts and lift the separator cover

“

2

”

up by a crane etc.

Mark the separator cover

“

2

”

and separator receiver tank

“

3

”

for reassembling them before

removing it.

⑦

Clean and degrease the connecting portion between separator cover

“

2

”

and separator receiver

tank

“

3

”

and check and confirm that there are no damages nor abnormalities.

⑧

Replace the oil separator

“

1

”

, gasket

“

4

”

,

“

5

”

and

flange of gasket (1 piece) by new ones.

⑨

At the point where gasket

“

4

”

and

“

5

”

contact the oil separator, staple

“

6

”

is to be pinned in four

points (diagonally) for prevention of static electricity. The staples

“

6

”

of gasket

“

4

”

and

“

5

”

should

be stapled not being overlapped.

※

HD-35 of MAX CO. LTD., should be used.

⑩

Tighten the fixing bolts of separator cover

“

2

”

according to the specified torque.

(Tighten the bolts diagonally and after tightening all the bolts, ultimately tighten them again in

full circumference.)

⑪

Tighten the fixing bolts of

flange according to the specified torque.

⑫

Connect re-assemble the pipes which were removed from the top of separator cover

“

2

”

.

※

Gasket

“

4

”

,

“

5

”

and gasket of

flange are to be coated with “THREEBOND 1212” at both faces

and then to be tightened.

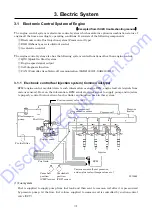

PDS400SC-6C3

A120182

PC12096

Bracket for fixing

solenoid valve

A

Tightening torque of

the bolts: 752.2lbf

・

in

(85N

・

m)[845kgf

・

m]

Lifting bolt (M12)

4

1

5

Tightening torque of

the bolts: 752.2lbf

・

in

(85N

・

m)[845kgf

・

m]

2

3

Lifting bolt (M12)

Position of the stapler

Position of the stapler

the upper gasket

Position of the stapler

the lower gasket

(4 places)

(4 places)

(Center)

The staples of both gaskets are to be fixed

with 45 degree changed so that they cannot

be fixed at the same position.

Discount-Equipment.com

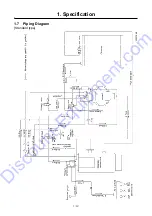

Summary of Contents for PDS400S-6C3

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m ...

Page 10: ...1 Specification 1 4 PC14064E Unit mm D i s c o u n t E q u i p m e n t c o m ...

Page 19: ...1 Specification 1 13 Aftercooler type A120195E D i s c o u n t E q u i p m e n t c o m ...

Page 20: ...1 Specification 1 14 1 8 Fuel Piping PC13053E D i s c o u n t E q u i p m e n t c o m ...

Page 101: ...5 3 5 2 Engine Wiring Diagram PC13087E PC13088 D i s c o u n t E q u i p m e n t c o m ...