2. Maintenance

2-8

2.4

Maintenance and Adjustment of Pressure Control Valve

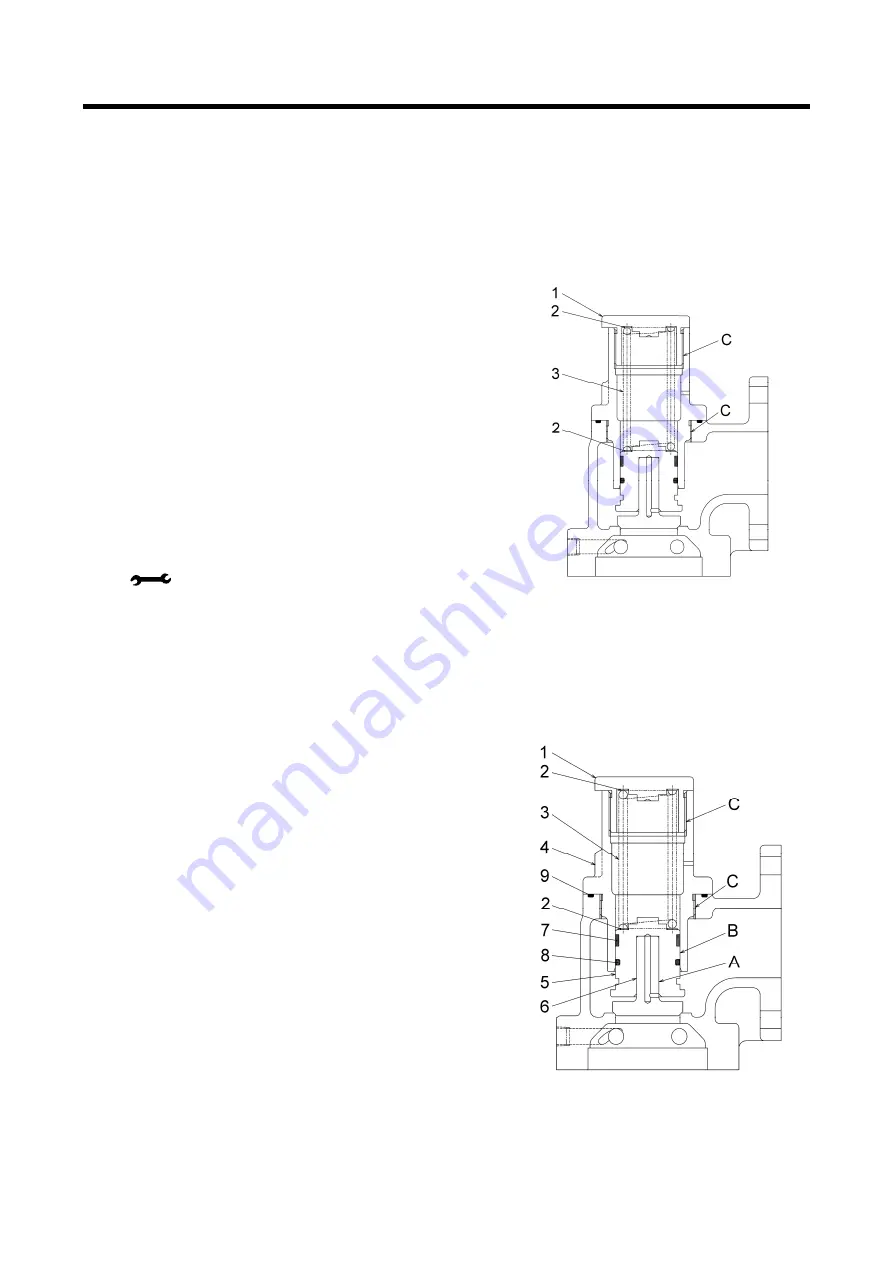

(1) Procedure of maintenance

In case that the discharge air pressure becomes lower than 51psi (0.35MPa) [3.5bar], it is necessary

to adjust the pressure of the pressure control valve according to the following procedures.

As it is possible that the O-ring has deteriorated or hardened, replace the O-ring even if the

replacement cycle has not yet been reached.

<Procedure>

①

Remove the pressure control valve cover

“

1

”

(opposite

side 65mm), and remove spring seat

“

2

”

. Then

change the spring

“

3

”

.

②

After installing the spring seat

“

2

”

, assemble the

cover

“

1

”

(opposite side 65mm).

③

After assembling, operate it to check and confirm

that there is nothing abnormal.

Before assembling, coat the threaded portion (C

portion) of spring seat

“

2

”

and of cover

“

1

”

with

lithium based all-purpose grease for prevention of

falling of spring seat and for prevention of thread

galling.

: 65 mm

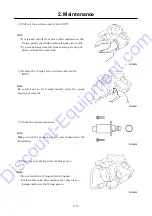

< Inspection procedures of piston, valve, ring and O-ring >

When the pressure is low even after the spring is replaced, disassemble and inspect it, in the

following procedures.

①

After checking and confirming that compressed air is

completely emptied, remove he cover

“

1

”

and then

remove the spring

“

3

”

.

②

After removing the cover

“

4

”

(opposite side 65mm),

and piston

“

5

”

and valve

“

6

”

, check the ring

“

7

”

and O-ring

“

8

”

for any hardness and any damages. If

piston

“

5

”

and valve

“

6

”

are found worn, replace them.

③

Coat the sliding surface (A portion) of valve

“

6

”

with

compressor oil.

④

Coat the sliding surface (B portion) of piston

“

5

”

with

grease.

⑤

Prevent the threaded portion (C portion) from galling

by coating the threaded portion with grease.

⑥

Coat ring

“

7

”

and O-ring

“

8

”

with grease.

⑦

Coat both sides of spring seat

“

2

”

with grease so that

it cannot fall when assembling.

⑧

Re-assemble the pressure control valve in reverse

order to disassembly.

⑨

After having assembled, operate to check and

confirm that the set pressure is 0.4+0.10/-0.05MPa.

PC13058

PC13059

Discount-Equipment.com

Summary of Contents for PDS400S-6C3

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m ...

Page 10: ...1 Specification 1 4 PC14064E Unit mm D i s c o u n t E q u i p m e n t c o m ...

Page 19: ...1 Specification 1 13 Aftercooler type A120195E D i s c o u n t E q u i p m e n t c o m ...

Page 20: ...1 Specification 1 14 1 8 Fuel Piping PC13053E D i s c o u n t E q u i p m e n t c o m ...

Page 101: ...5 3 5 2 Engine Wiring Diagram PC13087E PC13088 D i s c o u n t E q u i p m e n t c o m ...