2. Maintenance

2-1

2.1

Cautions for Overhauling

2.1.1

Precautions before starting work

(1) Work to be performed

It is very important to always plan in advance what facilities, tools, instruments, materials, oil, etc.

you will need to use; the exact locations and methods of performing inspection, adjustment, or

disassembly; and the key points of any repair work to be performed.

(2) Care not to spill oil

Use a pan to collect used compressor oil, engine oil when changing the oil or attaching or detaching

an oil line. If a large volume of oil is expected to flow

out, make

sure to drain any accumulated oil

from the reserve tank, engine oil pan in advance.

[Follow the designated regulations to dispose of compressor oil and engine oil.]

(3) Care when detaching parts

When disassembling a complicated part, put a matching mark to indicate the position of detached

parts for future reference. Make sure that the negative

-

cable

is detached from the battery

terminals before starting repair work.

(4) Use genuine parts

Make sure to use genuine parts when changing parts. Otherwise, it degrades performance and it

shortens machine life.

(5) Tools to be prepared

①

Measuring instruments

(e. g. tester, insulation resistance gauge etc.)

②

Tools

③

Torque wrenches

④

Jigs and specialized tools

⑤

Sealing tape

⑥

Molybdenum sulfide (tube type)

2.1.2

Disassembly and

re

assembly

①

Before removing nylon tubes, hydraulic/fuel hoses, it is necessary to clean the inside of machine

to prevent from entrance of dirt and foreign matters.

②

Perform disassembly work in a dust-free location whenever possible.

③

When disassembling parts, wash their outer surfaces and place them on a clean sheet of paper or

cloth, taking care not to contaminate or damage them.

④

Wash disassembled parts with diesel oil (cleaning solvent) after checking for contamination or

discoloration. However, do not wash rubber parts with diesel oil.

⑤

Be careful not to damage disassembled parts, they are precision built.

⑥

Replace consumables such as oil seals, O-rings, filters, oil, etc. with new items when reassembling

parts.

⑦

Apply “CALTEX MULTIFAK EP1” to O-ring surface. Never coat the sliding portion of oil seal

with grease because it loses sealing effect by stopping screw groove with grease.

⑧

When reassembling parts, place each part in the order of assembly and take care that no parts

are missing or misassembled.

⑨

When reassembling an assembled part (set part), be sure to replace it as an assembly.

⑩

Contamination or rusting may occur due to dust or humidity if parts are left in disassembled or

partly disassembled condition for a long time. Therefore, be careful to prevent dust or rust from

affecting parts if you have to leave the repair incomplete for a long period of time.

⑪

Check tightening torque and clearance when assembling parts.

⑫

Check the direction of rotation, speed, and oil leakage after assembly.

⑬

Before starting the machine after disassembly, run it at low idle to check for unusual noises, etc.

to prevent engine or generator damage.

⑦

Lithium based all-purpose grease

●

CALTEX MULTIFAK EP1

⑧

Diesel oil

⑨

Compressor oil

⑩

Cleaning cloths

⑪

Literatures (such as manuals etc.)

Discount-Equipment.com

Summary of Contents for PDS185S-6E1

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

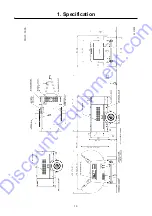

Page 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

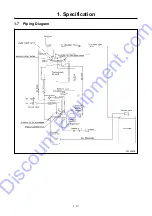

Page 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

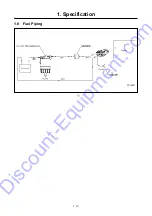

Page 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...