3. Electric System

3-6

<Manual regeneration procedure>

①

Regeneration required lamp

“

1

”

and error lamp

“

4

”

go on. At the same time, regeneration lamp

“

5

”

flashes. And also engine speed automatically

changes to 1,350 min

-1

.

②

Close service valve.

③

Keep pressing regeneration switch

“

3

”

longer than

3 seconds.

④

Regeneration required lamp

“

1

”

lights off and

cleaning exhaust filter lamp

“

2

”

goes on, then

regeneration lamp

“

5

”

changes to lighting on

instead of flashing and at the same time it

automatically starts purge operation.

⑤

Engine speed gradually increases up to

approximately 2,200 min

-1

.

⑥

Under this state, manual regeneration operation is

performed about 30 minutes.

(

※

)

⑦

All lamps go off and manual regeneration operation

comes to end, and it returns to normal engine speed

and normal operation starts.

※

Time of regeneration varies upon the ambient

temperature.

●

When continuing operation about ten hours without

conducting manual regeneration even while

regeneration required lamp

“

1

”

is lighting, it will

be impossible to conduct manual regeneration and it

leads to low idling operation only. In this case, it

becomes necessary to clean DPF (Diesel particulate

filter). Please contact our nearest dealer.

When DPF regeneration required lamp goes on, take immediate specified action to

conduct manual regeneration.

If it is continuously operated without manual regeneration, excessive soot will

accumulate and it could damage DPF due to abnormal burning, and it could cause a

fire.

Do not stop engine during enforced regeneration operation, except for unavoidable

conditions.

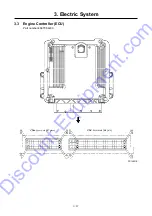

A130992

Regeneration required

ON

OFF

OFF

Manual regeneration

ON

1

3

5 2

4

Discount-Equipment.com

Summary of Contents for PDS185S-6E1

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Page 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

Page 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

Page 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...