Page 11

Air Techniques, Inc.

While the compressor aggregate is in operation the accumu-

lating condensate is separated by being conveyed through

the cyclone separator and, in a second step, through a

refrigerant dryer and then separated to the waste water

system� This process is carried out automatically using a

valve in the cyclone separator and the refrigerant dryer

controller, depending on the level present�

A special load controller monitors the compressor aggregate

operation and implements an alternation of compressor

operation on a rolling system� The alternation is carried

out according to the number of operating hours each

individual compressor aggregate has performed�

The pressure in the tank can be read off using a pressure

gauge and also at the display panel�

Auxiliary operation

Depending on the amount of compressed air required and

the particular set up of the compressed air network it may

be necessary for two (or more) compressed air stations

to work together on one network� In this particular set up

one compressed air station operates in main operation,

the other(s) in auxiliary operation�

The settings for auxiliary operation are carried out on

initial set up and configuration of the complete unit using

the display panel� In auxiliary operation the control range

for cutting in and cutting off pressure for the compressed

air station is lowered by 1�5 psi (0�1 bar)� In this way the

compressed air station aggregates switch in main and

auxiliary operation alternately on and off�

5�3 Emergency mode

Emergency mode can only be used for short periods in

order to maintain an emergency supply of compressed

air in the cases of a possible defect in the system�

Turning the switch (4) to the Emergency mode setting "1"

switches on the first compressor aggregate and it starts

up in pressure free state�

After approximately 3 seconds the switch (4) can be rotated to

position "2"� The solenoid valve opens the pressure line and

the compressor aggregate begins to supply the pressure tank�

The compressor aggregate then runs in continuous operation�

The alternation of aggregates no longer takes place�

When no air is taken from the tank, the pressure in the tank

increases to 145 psi (10 bar) and will be maintained at this

level by the opening of the safety valve� The safety valve

produces a loud venting noise when it is in the open position�

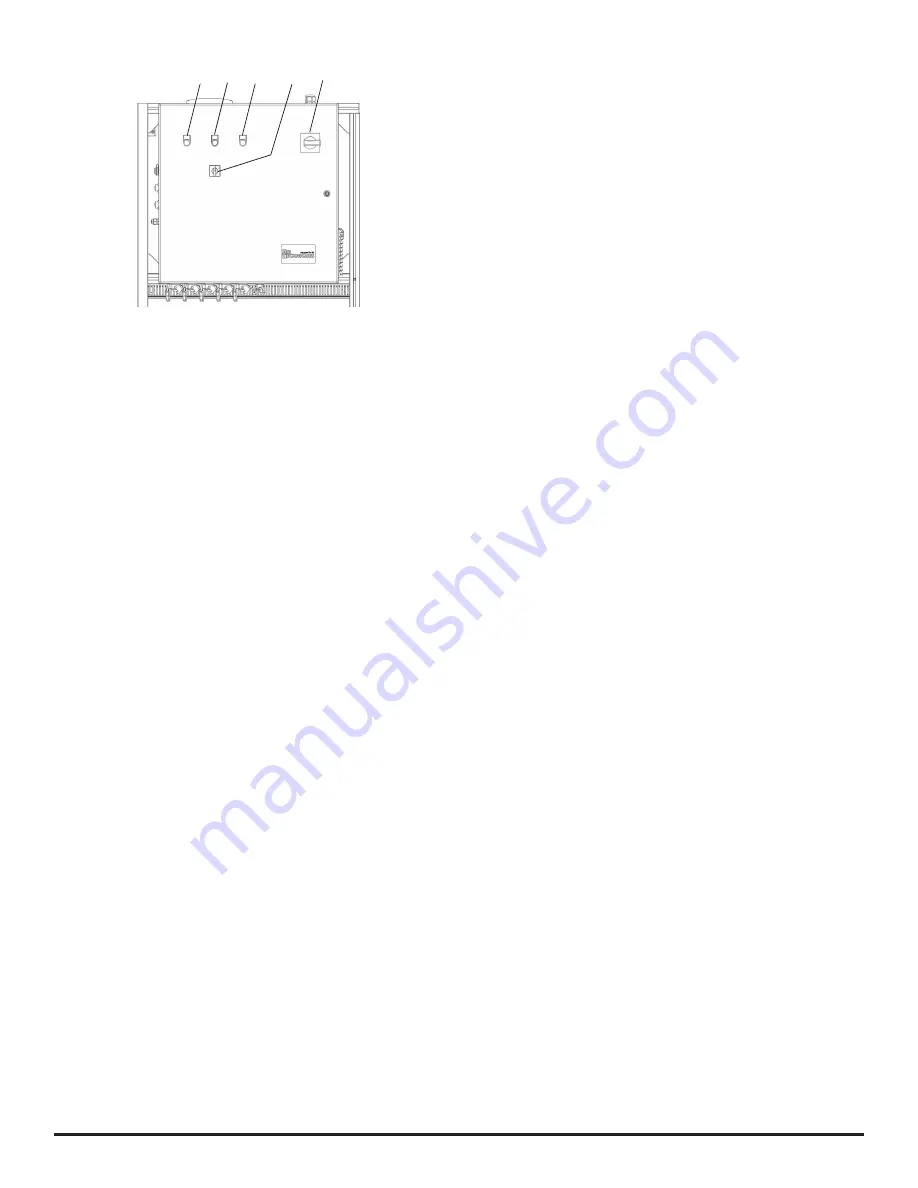

Fig� 5: Control unit

1 Red LED "Fault"

2 Blue button "Reset"

3 Green LED “Run”

4 Emergency mode switch

5 Main power switch

5�1 Start operation

After switching on at the main power switch of the control

unit the refrigerant type dryer is switched on and cools

the heat exchanger to its normal operating temperature�

Depending on the actual ambient temperature this cooling

can take up to 3 minutes (see the temperature display on the

refrigerant dryer)� After approx� 60 seconds the controller

switches on the first compressor aggregate� At about 3

seconds the next compressor aggregate will be switched

on� A sensor monitors the pressure inside the tank, which

is shown by the display� Upon reaching the set pressure in

the controller (see section Technical Data) the aggregates

will be turned off sequentially�

5�2 Normal operation

A sensor monitors the pressure in the tank vessel� When

compressed air is taken from the pressure tank, the pressure

within the tank falls� At 109 psi (7�5 bar) the first compressor

aggregate switches on� If the pressure within the tank continues

to fall, then further compressor aggregate are switched on

consecutively according to the switch-on pressures set (see

4 Technical data)�

Each compressor aggregate starts up in a pressure free

state� After approximately 3 seconds the solenoid relief

valve opens the pressure line and the aggregate begins

to supply the pressure tank�

When the pressure within the tank rises, the compressor

aggregates are switched off one after the other as soon

as the preset cut off pressure of 116 psi (8 bar) has been

reached (see 4 Technical data)�

When more compressed air is taken from the tank the pressure

falls and the next aggregate switches on automatically� When

the tank pressure falls below 15 psi (1 bar), the compressed

air station switches over to emergency mode (one compressor

aggregate remains in continuous operation)�

1

3

2

5

4

Summary of Contents for AirStar AS120

Page 2: ......