7.

Service and Maintenance

Service and maintenance are vital for problem-free opera-

tion of an Airmaster unit and its equipment. The majority

of servicing consists of cleaning and inspection of the

condensate system and filter change. We recommend that

all service is performed by authorised experts.

Please contact your service partner by phone or mail to

agree service provision.

7.1.

External Cleaning

NB: The air handling unit must be switched off before

cleaning.

To remove dirt from the control panel, sensors, cooling

module and air handling unit, use a soft, damp cloth and

clean water, or water with a mild detergent added (e.g.

washing up liquid).

NB: Do not use aggressive substances (e.g. turpentine)

or sharp objects (such as a scraper) to clean the ventila-

tion system components.

The extraction grille and air vents must be regularly cleaned.

We recommend vacuum cleaning using a soft brush nozzle.

The space between the air handling unit and ceiling can be

dusted using a feather duster. A soft brush vacuum nozzle

can also be used if there is sufficient room.

7.2.

Internal Cleaning

Internal cleaning is recommended when changing filter. If

dirt gets in to an Airmaster unit/cooling module, remove

with a vacuum cleaner or soft brush.

REMEMBER! The unit must be switched off and discon-

nected from the mains before the access covers on the

unit and cooling module can be opened.

NB: Check the cleanliness of components when per-

forming internal cleaning. This applies in particular to

the counterflow heat exchanger and fans.

7.3.

Cleaning the Condensate System

N.B. The condensate system must be cleaned minimum

annually and must be controlled at every filter change.

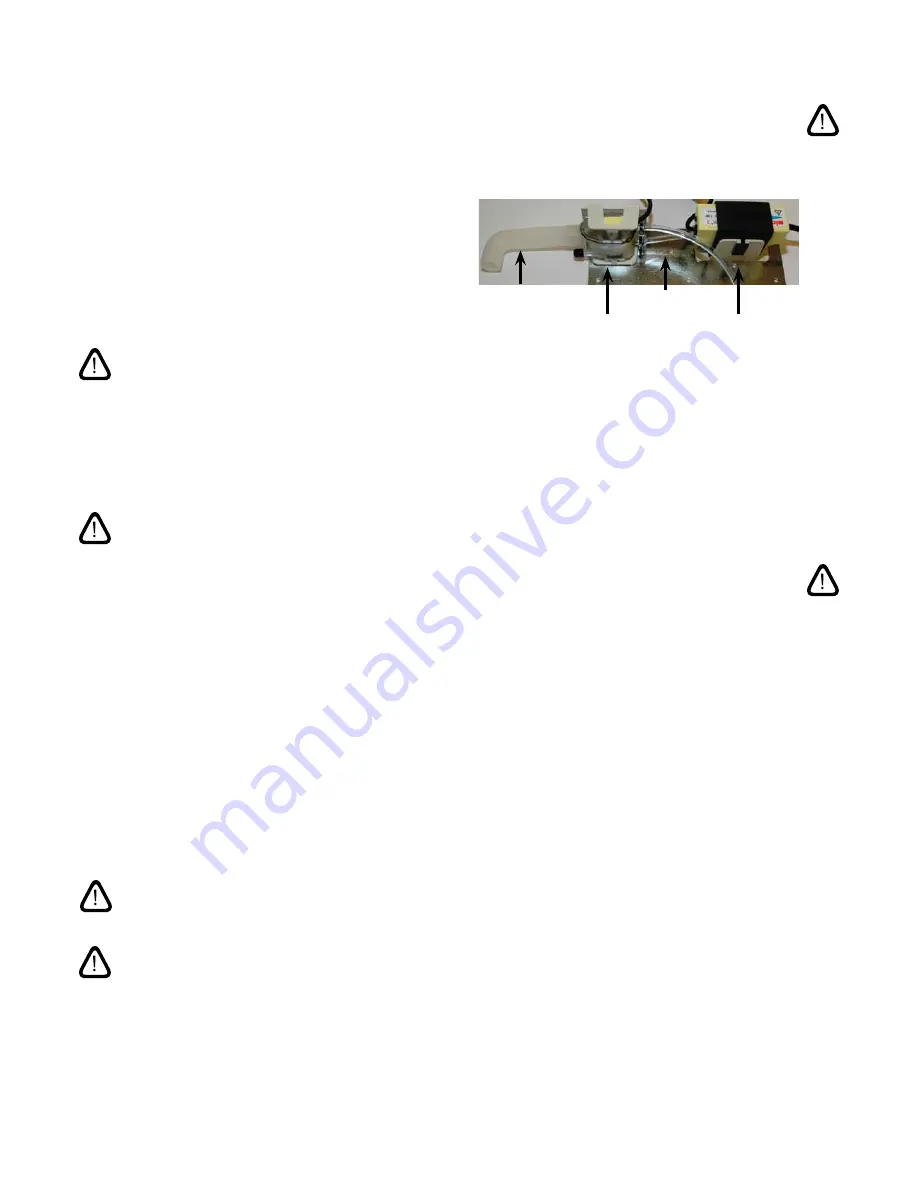

Condensate pump:

Supply hose

Drain hose

Float housing

Condensate pump

The condensate pump is fitted as standard on the cooling

module, and is an optional extra for the air handling unit.

AMP 1200: The condensate pump is behind a service access

cover under the extract air panel.

• Remove the condensate tray (cooling modules only).

• Remove the float housing and supply hose.

• Open the float housing cover.

• Clean all individual parts.

• Replace all the above in reverse order.

NB: All condensate hoses in the condensate system

must be secured again with a suitable hose clip.

• Pour approx. a half litre water into the condensate

tray, switch on the power briefly and check that the

water is pumped out and that there are no leaks.

Condensate tray:

A condensate tray is fitted as standard to all air handling

units and cooling modules.

The plug, drain house and tray can all be easily removed for

cleaning the drain and hose. We recommend cleaning the

drain and hose when changing filter.

27

Summary of Contents for AML 100

Page 39: ...39 Notes ...