Page

14

of

30

15C0233-00 Rev A

SSC4500DX

9/23/2020

6.0 Installation and Initial Startup

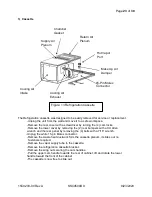

The Sterile Storage Cabinet is designed to be used in either an open exam room environment,

utility closet, or alcove. The unit generates 120-130 cfm of 95-105°F air to maintain interior

cabinet conditions, which is exhausted at the top surface of the unit. The cooling air intake vent

is located on the bottom of the unit. Both areas should be clear and unobstructed always or the

unit will fault on a high-pressure limit.

The unit has an integrated steam humidifier that will add humidity to the cabinet if the RH falls

below the humidity setpoint. The humidifier should never be run dry and there are safeties to

protect against this condition. The onboard water bottle must be filled. To add water, simply

slide the lock to the right and lift the cap. Fill carefully while monitoring the water level through

the sight glass on the front of the unit. Once full, close the cap, dry any residual water in the fill

port, close the lid, and lock. If any water has spilled on the front of the unit or floor, clean and dry

immediately.

The unit can be plugged into any 120VAC 15amp wall outlet.

IMPORTANT: If plugging into a RED or backup circuit, consult with the facilities manager.

The unit will power up and perform a self-diagnostic on the controls and sensors. After a 30-sec

delay, the evaporator fan will start and provide air flow to the interior of the cabinet, establishing

a positive pressure. The refrigeration system will energize 30 seconds later and start the

process of conditioning the cabinet.

The unit

’s internal conditions are pre-set to nominal values. The unit must be run for 24hrs prior

to loading any equipment or supplies. The cabinet must acclimate to the local conditions and

thermally stabilize. The temperature and humidity will fluctuate during this 24-hour period.

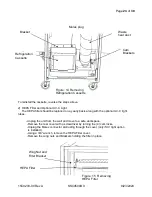

Utility Closet or Alcove Installation

When the unit is installed in a utility closet or alcove, it is critical to have sufficient air flow to

properly cool the unit. The space around the bottom of the unit must free and clear to allow

room air to enter through the bottom of the unit. The utility closet or alcove must be vented to a

large open-air space above the ceiling or other open space per facility guidelines. The optional

Ceiling Exhaust Kit can be used. The exhaust vent on t

he top of the unit will accept standard 6”

flex duct not to exceed 20 ft in length. It is critical to ensure there are no sharp bends, kinks or

crushed duct, as this will affect the performance of the unit.