17 Technical Information

Connection J1 Remote I/O Interconnections

222/288

Turbo-V 1001 Rack Controller User Manual / 87-901-033-01

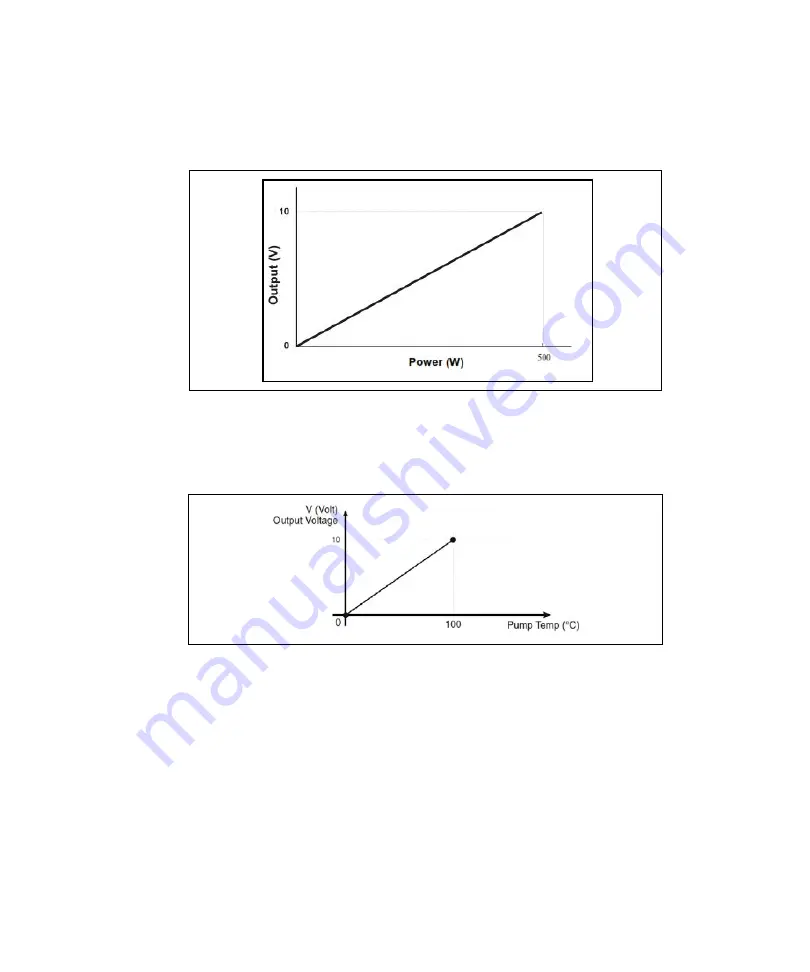

The analog output power related is showed in the following diagram:

Figure 12

The analog output pump temperature related is showed in the

following diagram:

Figure 13