5

DESCRIPTION OF THE ACCESSORY

The Multichiller-Evo allows you to manage the switch-on/off and timed pro-

gramming of the chillers (up to nine) installed on the system. The accessory

will manage the power demand by the utilities, sequentially powering the

chillers to meet the power demand; this will be possible thanks to the fun-

ctioning logics settable on the Multichiller-Evo software through its touch-

screen.

The Multichiller-Evo is supplied within a wall-mounted IP66 electric box and

an additional IP66 electric box with expansion board for connecting the in-

put and output probes of the water produced. The connections to be made

depend on the type of chiller (air-water or water-water) and the accessory

has been designed for double ring applications (as shown in the following

diagram); for any other application than the recommended ones, contact

the company.

RS485

RS485

RS485

RS485

Chiller (1)

Chiller (2)

Chiller (3)

Chiller (n)

5

6

5

6

5

6

5

6

pCOe

Multichiller-Evo

2

1

3

4

Recommended system (double ring with storage tank and circuit breaker)

Index

Component

1

Condensation probe (placed externally for air/water machines; on the condenser return for

the water/water machines)

2

pCOe expansion board (supplied)

3

Circuit breaker temperature probe 1

4

Circuit breaker temperature probe 2

5

Pump

6

Non-return valve

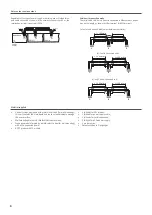

1. The accessory can manage systems with chiller scroll, screw or centrifu-

ge; however, the chillers connected to the Multichiller-Evo must all be

of the same type (air-water or water-water);

2. The Multichiller-Evo does not manage any load outside the chiller; val-

ve pumps or other specific loads cannot in any way be directly control-

led by it;

3. Each chiller must be provided with internal or external pump, driven

by the chiller board;

4. The evaporator of each chiller must have adequate parts to prevent the

passage of water in case the chiller is not operating (non-return valves

have been used in the example);

5. If the Multichiller-Eco does not manage multipurpose units, it is ne-

cessary to connect one of the supplied probes to the analogue input

U1 (terminal board J2); this probe must be positioned so as to provide

information on the condenser temperature:

•

Outside if the chillers are air-water;

•

On the source side if the chillers are water-water;

6. Each chiller communicates with Multichiller-Evo via Modbus network;

to achieve this connection, each chiller must be provided with appro-

priate board for serial communication via modbus;

7. The probes positioned in the circuit breaker storage tank and con-

nected to the pCOe board must be set via software (through the proce-

dure indicated on page 27) to determine which of the two will be used

to read the system demand;

8. If you want to activate the system’s set-point compensation function

with climatic curve, use a NTC temperature probe (supplied) connected

to the multifunction input U2 (terminal board J2), which must be set

(through the procedure indicated on page 32) to associate the value

read by the probe to the SET “COMPENSATION function;

9. The supplied temperature probes have a 15 m long cable;

10. If you want to insert the Multichiller-Evo within a BMS-managed sy-

stem, you will need to purchase and install an AER485P1 serial board.

PAY SPECIAL ATTENTION:

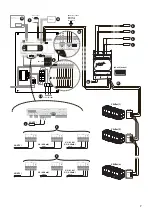

230V~50/60Hz

Summary of Contents for Multichiller-Evo

Page 2: ......