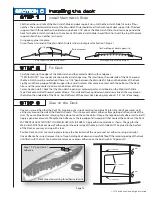

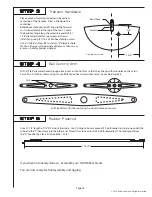

Correct

Incorrect

Incorrect

Fillet

Fillet

Correct

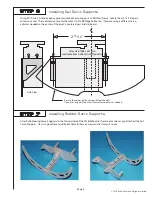

87

°

SECTION D

STEP 1

Finishing the keel

Test fit the Keel Bulb (lead ballast)

STEP 2

Attach the Keel Bulb

STEP 3

Fillet and Finish

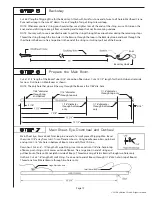

Slide bottom threaded rod into the pre-drilled hole in Keel Bulb and check for proper alignment.

Align centerline of Keel Fin with centerline mark in Keel Ballast made by the molding process.

Check fore and aft tilt of the Keel Bulb. The Keel Bulb

should already be drilled at an 87

°

angle as shown.

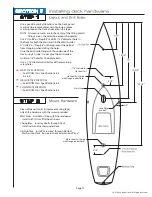

Once you are satisfied that the Keel Bulb fits properly, apply a generous amount of Thick CA adhesive to both surfaces

to be joined, including the Threaded Rod and the hole in the Keel Bulb. Put parts together and quickly check visually

to be sure alignment is correct. Hold parts together with one hand and spray with CA glue accelerator. Hold until CA

sets.

If alignment looks good, move on to step 3. If not, you can "crack" the joint, push into place, re-glue or remove Keel Bulb,

and try again.

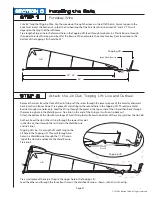

Using Auto Body Glazing Putty (bondo), build a fillet along both sides of the seam between

the Keel Fin and Keel Bulb. The fillet may be up to 1/2" radius in size.

See ODOM Class Specification 3.3.8

Coat entire surface of the Keel Bulb with Aluzine Epoxy. Allow to dry, sand smooth.

Repeat until all "low spots" are filled and "high spots" are sanded down. Final sand with

320 grit or higher sandpaper. You may paint your Keel Bulb white or paint your Keel Fin

and Keel Bulb to match your Hull.

Page 14

Keel Fin

Keel Bulb

Check that the Keel Bulb aligns with the centerline

up and down.

NOTE:

If the Keel Bulb does not align with the

Keel Fin in all three directions as shown,

adjust by bending the Threaded Rod slightly.

See ODOM Class Specification 3.3.6

Side View

Top View

Top View

© 2010 by Adrian Olson. All rights reserved.