Technical manual ADITRAT

5

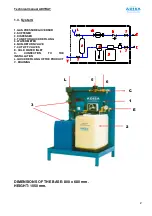

2.3.1. GENERAL NOTES FOR THE VALVE INSTALLATION:

1.- The softener must be installed very close to a draining point in order to discharge in it the

water coming from the regeneration processes.

2.- The drain pipe should be as shortest as possible, with a pass of ½” at least. It should not be

installed in a higher point than the draining connection of the softener in order not to limit the

suction process of the brine.

3.- The drain outlet leading to the drain should be free fall, without any obstacles interrupting or

reducing the connection diameter.

4.- Be sure that the softener and the salt tank are well levelled. Place them on a clean and plate

surface.

5.- Before realizing the electric connections, check that the voltage and the frequency from the

mains correspond to the ones of the valve (220V, 50Hz).

6.- The valve power point should be provided with a good earth connection.

2.3.2. INSTALLATION OF THE SOFTENER

1.- Connection of the drain pipe.

- The connection must be realized in the point marked in the valve with the word DRAIN,

which is situated on a side of the programmer head.

2.- Assembly brine injector.

- This series of valves are equipped in our factory with the injector nr. 3. The function of the

injector disk is to create the necessary vacuum to extract the brine from the salt tank and

inject it into the softener.

3.- Correspondence pressure-injector disk.

4.- Salt tank.

- This is the procedure to measure the height of the brine valve floater:

a) Pour into the tank as many litres of water as the litres of resin contained in the softener. It

is recommended to add a 20% more of water as a safety margin.

b) Fill the tank with salt up to the level of the chimney.

c) Wait a few minutes until the salt settles down.

d) Put the valve floater at the same height as the level the water has reached inside the

chimney.

- It is necessary to maintain the level of the salt ALWAYS above the level of the floater after

the first regeneration.

Summary of Contents for ADITRAT

Page 15: ...13 ...