Technical manual ADITRAT

3

2. WATER SOFTENER

2.1. GENERALITIES:

The water, while crossing the earth strata, becomes rich of mineral salts that represent its total

salinity. The presence of some of these salts, such as calcium and magnesium, determines its

hardness, which is the main cause of scale and damages to the water installations (control valves,

security valves, purgers, boilers, heaters…).

It is convenient to install a SOFTENER that, by means of synthetic resins, can absorb the calcium and

magnesium salts and eliminate the excessive hardness.

SCALE:

Scale is another serious problem caused by the water hardness. Pipes, through which the hard water,

cold or hot, is circulating, can get obstructed. Scale is not necessarily produced when the water

temperature is high, any variation on the original water temperature is sufficient to generate it.

With the progressive increase of scale in a water heater, or boiler, it happens that the boiler can need

more and more energy to transfer the same heat, coming to consume by 30% more than if it would

work with soft waters. Furthermore, this can cause overheating of the materials with the consequent

break of the equipments. All these problems disappear with the use of soft or decalcified water.

THE SOFTENER:

There are various effective methods to reduce the water hardness, the most appropriate are:

deionization, distillation, reverse osmosis and the ionic interchange (decalcification).

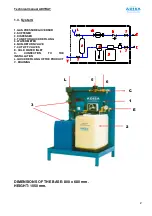

The softener is composed of a tank for resins and another one for salt (salt is necessary for the

periodical regeneration of the resins). The unit is completed by a programmer valve regulating the

washing cycles necessary to the equipment’s efficiency.

2.2. OPERATION

The water decalcification is due to an interchange of ions (calcium-magnesium for sodium) at the

moment the water passes through a bed of special resin. Once the resin gets saturated, it must be

washed or regenerated with salt.

In order to preserve the life of the resin, its regeneration must be realized according to the following

guidelines:

First of all, a good cleaning in order to eliminate all the impurities that may have settled down on the

resins.

Secondly, proceed to wash the resins with brine (salt dissolved in water).

Finally, a good rinsing to eliminate the exceeding salt.

Summary of Contents for ADITRAT

Page 15: ...13 ...