USER’S MANUAL

V-line 899x.xxx/LPG HYBRID

44

ATTENTION!

WHEN WOULD BE USED THE NON-CERTIFICATED DISPENSING HOSE, THE EXPLOSION CAN BE

INICIATED!!!

13.9.

LPG dispensing nozzle

The dispensing nozzle for liquefied gas is a final component of the LPG dispensing module. The connecting

end of the dispensing nozzle is fitted with a rubber sleeve ensuring tight connection between the

dispensing nozzle and the vehicle tank filler. The nozzle is also fitted with protective cover made of

antistatic material at the place of operator's hand contact as a protection against sudden cooling of the

nozzle metallic parts. The dispensing nozzle is designed to provide accurate connection and low physical

effort for handling required. It is recommended to grease the mechanism of the nozzle connecting end

and the lever pin with silicone oil once per three months. It can be carried out by the filling station

operator. Replacement of sealing and the nozzle itself can be only carried out by a skilled worker of the

service shop.

13.10.

Dismantling of covers

It is carried out in required scope during installation, routine maintenance, minor repairs and

modifications of electric or hydraulic parts.

The original location of covers must be held in remounting!

13.10.1.

Covering of duplex hydraulic modules

To make the interior of hydraulics accessible the door shall be dismounted by unlocking, tilting and

slipping out.

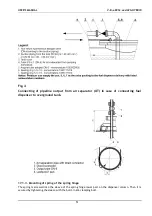

To make the entire interior of the hydraulic module accessible it is necessary to dismantle the module

cover by loosening six M8 nuts, three on the column and three on the foundations. Four bolts positioned at

the upper part of the column shall be loosened for lifting the column cover off to make the distirbution

box accessible. Then the column can be tilted and slipped out.

Take care of the magnetic switch cable

for controlling the lifting of the dispensing nozzle.

13.10.2.

Covering of counter case

Face covers are disassembled by unlocking the cover and lifting it upwards on hinges. The cover lifted is

screwed by means of the cover holder in the upper position. This allows the access to the electronic

counter and other components located in the box.

Any handling the electric and electronic parts may only be carried out by a specialist who is responsible

for the safety of the equipment. The IP 54 protection may not be affected during the counter case

handling.

It is necessary to check the gasket prior to remounting the cover. Damaged gasket shall be replaced.

13.10.3.

Dismantling of the metering unit

Dismount the covers, unscrew the bolts connecting the meter to the joining piece. Disconnect the flange

connection to electromagnetic valve, dismount the bolts of the integrated detector and remove it from

the meter. Reverse procedure is used for remounting the meter.

13.10.4.

Dismantling of the electromagnetic valve

Disassemble the covers of hydraulics, disconnect the joining tube by means of a cap nut. Then dismount

the fixing bolts of the valve flange. Release the wires of electromagnetic spools in bushings after removing

the covers of the hose module. Then disconnect the wires in the counter case and remove the valve after

withdrawing the wires from the wire bundle. Reverse procedure is used for mounting the valve.

ATTENTION!

After any service intervention and remounting it is necessary to check visually the tightness of

bolted connections and possible fuel leakage shall be eliminated.