Actionair DWFX-F Installation Guide

6

Swegon reserves the right to alter specifications. 20210408 - LNNN00354 (3.0)

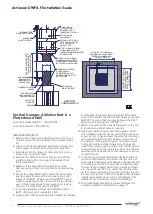

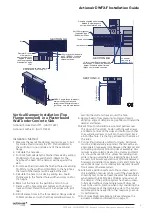

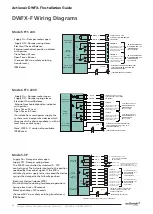

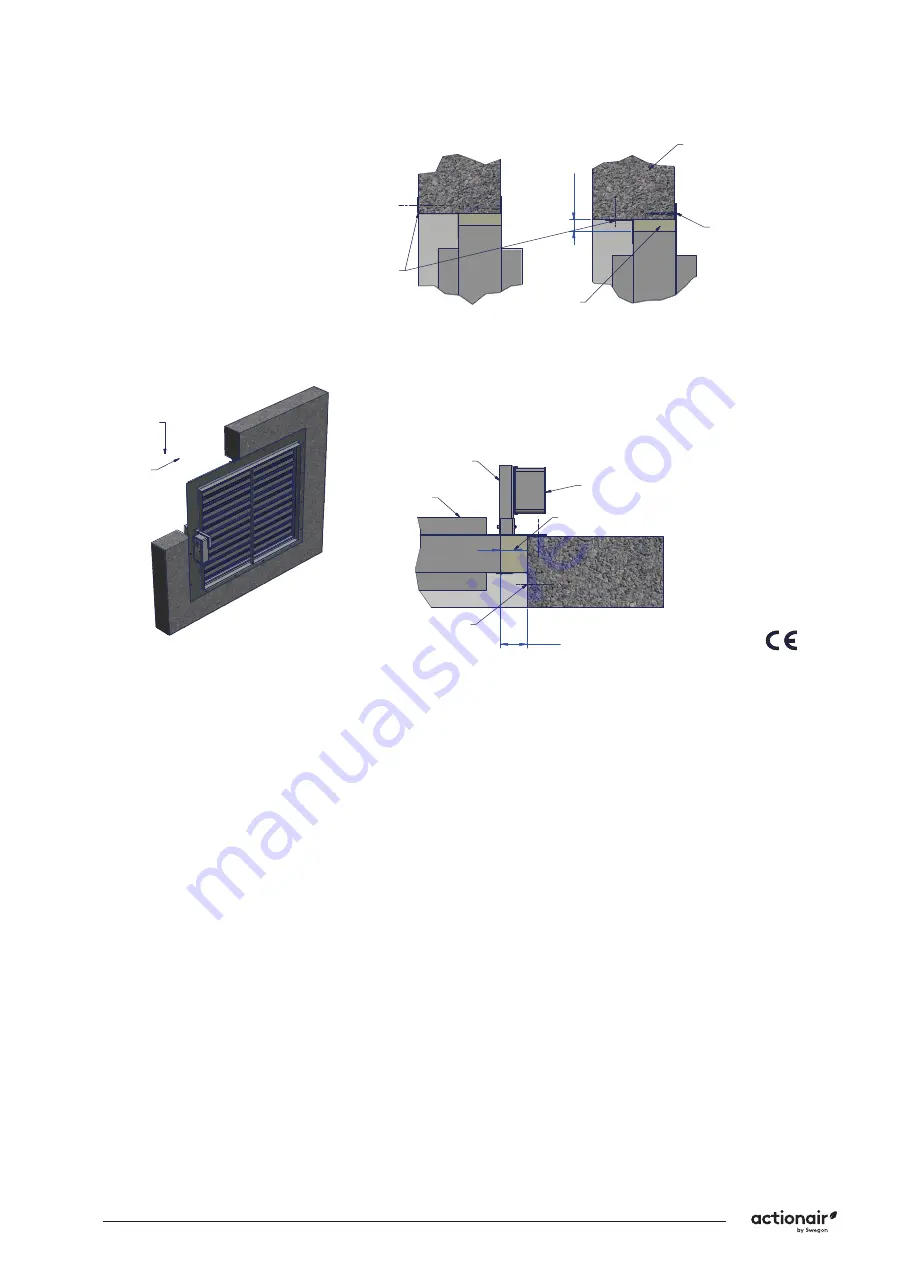

Vertical Damper Installation in

a Masonry Wall

Actionair SmokeShield PTC - [AA/F10706]

Actionair FireShield - [AA/F10707]

Installation Method

1.

Drill clearance holes in the damper flange at 150mm

centres.

2.

Install the damper and fix through flange using fire

rated fasteners, min ø4mm.

3.

Back fill between damper casing and wall, with mine

-

ral/stone wool and secure in place with angle retaining

flanges, fixed in corners, or with Z shaped retaining

flanges, to give the option of face fixing onto wall.

Note: either angle or Z retaining flanges to be supplied

by others.

4. Note: dampers supplied with cleats welded to top

flange to assist with installation only.

5. Connecting ductwork omitted for clarity. Ductwork

must be independently supported. There must be an

appropriate break-away joint between the damper and

connecting ductwork on both sides of assembly. Alu-

minium rivets or plastic cleats, clips, clamps and bolts

etc. should be used for this, unless fire resisting duct-

work is being used where fire resisting fixings should

be used. A minimum of 200 mm between fire dam

-

pers installed in separate ducts and 75 mm between

fire damper and a construction element (wall/floor).

6. Alternative partition systems to those shown within

this installation manual can be used if they have been

Comments:

Rev:

Drawn By:

swehrle

Approved By:

N. Harris

1 of 1

Reference No:

S. Gore

Date:

Date:

By:

Date:

20/03/18

31/05/11

20/03/18

Date:

F

Checked By:

Sheet

Rev

AAF10706

Description:

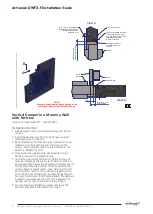

If your proposed installation details

differ from that shown here, please

discuss this with the Building Control Authority

(BCA), referencing this documentation,

associated fire tests, assessments, and other

documentation shown below. Deviation from

this drawing requires the approval of the

relevant authority.

Installation Detail

Connecting ductwork omitted for clarity.

Ductwork must be independently supported.

There must be an appropriate break-away

joint between the damper and connecting

ductwork on both sides of assembly.

Aluminium rivets or plastic cleats, clips,

clamps and bolts etc. should be used for this,

unless fire resisting ductwork is being used

where fire resisting fixings should be used. A

minimum of 200 mm between fire dampers

installed in separate ducts and 75 mm

between fire damper and a construction

element (wall/floor).

³

IF YOUR PROPOSED

INSTALLATION DETAIL DIFFERS

FROM THAT SHOWN, YOU MUST

DISCUSS THIS WITH THE

BUILDING CONTROL AUTHORITY

(BCA), REFERENCING THIS

DOCUMENT AND THE

ASSOCIATED FIRE TESTS,

ASSESSMENTS AND OTHER

DOCUMENTS SHOWN BELOW.

DEVIATION FROM THIS DRAWING

REQUIRES THE APPROVAL OF

THE RELEVANT AUTHORITY.

EXPLANATION:

2 Hour fire, smoke rating, & 2 hour fire integrity.

The damper must be installed in accordance with the manufacturer's

recommendations and HEVAC/HVCA publication HVC6/5/83 rev 1

APRIL 2002.

This solution has been assessed by BRE to BS476 PT 20 for 2 hours

and tested by BRE to BS-EN1366-2.

Acceptance of this solution must be sought by the system designer

(In writing) from the appropriate LA prior to installation.

Requirements for access openings for inspection and cleaning

purposes are provided in HVCA DW/144 specification for sheet metal

ductwork.

Access provision must be allowed to permit jointing of ducts to fire

damper. It may be necessary to install access doors on both sides of

the partition so that the ducts can be fitted from inside the damper.

© Swegon Air Management Limited

South Street, Whitstable, Kent CT5 3DU

Tel: +44 (0)1227 276100

Fax: +44 (0)1227 264262

www.swegonair.co.uk

Applicable Test Report to

BS EN1366-2:

BRE 256493

MINUTES

ES 120

Fire Resistance

Integrity and Leakage

E

EC1770

MJB 20-02-18

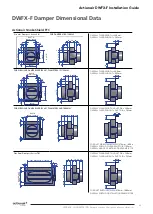

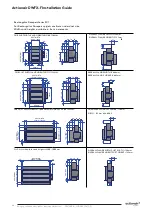

Damper Size Range (mm)

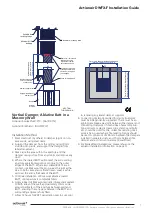

VERTICAL APPLICATION

SMOKE DWFX-F

200 X 200 to 1000 x 1000

VERTICAL BLADES;

DAMPER CAN BE INSTALLED WITH

THE BLADES IN THE VERTICAL

ORIENTATION WITH THE ACTUATOR

MOUNTED AT EITHER THE TOP OR

BOTTOM.

F

EC1830

RTC 20/03/18

shown by test to have at least the same fire resistance

when tested to BS EN 1364-1:1999 as is required of

the damper. If the partition system has been success-

fully tested without stone mineral wool it does not

have to be used in practice when only considering the

fire performance of the complete system. The mineral

wool may still be needed for other reasons e.g. acous-

tic performance.

7.

For SmokeShield installations, please reference the

actuator installation information on page 11.