Suburban Dynaline 3 A&E Manual 12/2021 Rev.2

8

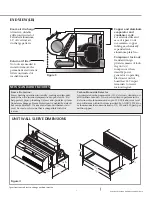

SPECIFICATIONS

DYNALINE

™

3 SERIES

Dynaline

™

3

General Data

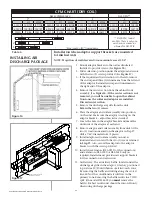

Model

DYNA07AC DYNA09AC DYNA12AC DYNA16AC

Rated Heating Input (BTU/h)

12,000

12,000

18,000

20,000

Rated Heating Output (BTU/h)

9,840

9,840

14,580

16,000

Thermal Efficiency (TE)

82%

82%

82%

82%

Rated Cooling Capacity (BTU/h)

7,600

9,500

11,500

15,000

Sensible/Latent Cooling

65/35

69/31

65/35

65/35

EER

11.60

11.20

10.40

9.50

Rated air flow: fan only (CFM)

Hi cool/low cool (CFM)

Hi heat/low heat (CFM)

260

300/250

320/260

260

300/250

320/260

300

390/300

410/300

340

400/330

420/340

Weight lbs (kg)

180 (82)

180 (82)

180 (82)

185 (84)

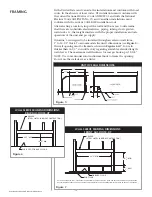

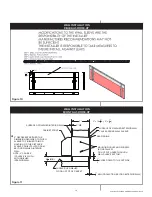

Minimum Installation Clearances

Outside:

Rear to nearest obstruction

3 feet

3 feet

3 feet

3 feet

Top, sides to nearest obstruction

0

0

0

0

Centerline vent to window

9”

9”

9”

9"

Inside:

Cabinet front to nearest obstruction

12”*

12”*

12”*

12"

Cabinet sides to nearest obstruction

1”

1”

1”

1"

Cabinet bottom to floor (for return air)

0

0

0

0

Cabinet top to ceiling

12”

12”

12”

12"

*Obstruction must be removed for service of unit.

Condenser Fan

Fan Blade Diameter

12"

12"

12"

12"

Number of Blades

4

4

4

4

Pitch

25º

25º

25º

25º

Condenser Fan Motor RPM

1,500

1,500

1,500

1,500

Full Load Amps

0.5

0.5

0.5

0.5

Condenser Coil

Type

Copper/Aluminum

Coil Area

364 sq. inches

Rows

3

3

3

3

Fins per Inch

12

12

13

13

Evaportator Coil

Type

Copper/Aluminum

Coil Area

234 sq. in. 234 sq. in. 260 sq. in. 260 sq. in.

Rows

3

3

3

3

Fins per Inch

11

11

11

11

Refrigerant Metering

Capillary

Room Air Fan Motor

Speed

2

2

2

2

RPM High/Low

1260/1130 1260/1130 1520/1400 1520/1400

Full Load Amps

0.3

0.3

0.5

0.7

Min. Wire Size (60º Copper)

#18 AWG #18 AWG #18 AWG #18 AWG

Electrical Data

Model

DYNA07ACA DYNA09ACA DYNA12ACA DYNA12ACV DYNA16ACA

Volts/Phase/Cycle

208/230-60-1 208/230-60-1 208/230-60-1 277-60-1

208/230-60-1

Total Amps Cooling/Heating

3.3/1.0

3.8/1.0

5.1/1.0

4.8/1.0

7.5/1.2

Total Watts Cooling/Heating

675/150

855/150

1125/150

1125/150

1550/260

Min. Wire Size (Copper)

#14 AWG

#14 AWG

#14 AWG

#14 AWG

#14 AWG

Protection-Fused

2-15 amp

2-15 amp

2-15 amp

2-15 amp

2-15 amp

Protection-Circuit (HACR type)

Dual-15 amp Dual-15 amp Dual-15 ampDual-15 amp Dual-15 amp

Unit Plug:

Amps

NEMA Rating

15 amp

6-15 P

15 amp

6-15 P

15 amp

6-15 P

15 amp

6-15 P

15 amp

6-15 P

Receptacle:

Type

Amps

NEMA Rating

Tandem

15 amp

6-15 R

Tandem

15 amp

6-15 R

Tandem

15 amp

6-15 R

Tandem

15 amp

6-15 R

Tandem

15 amp

6-15 R

Compressor Data

Model

DYNA07ACA DYNA09ACA DYNA12ACA DYNA12ACV DYNA16ACA

Type

Hermetic Rotary

Refrigerant Type (HCFC)

R410A

R410A

R410A

R410A

R410A

Refrigerant charge

26 oz.

26 oz.

32 oz.

32 oz.

36 oz.

Rated Load Amps

2.9

3.9

4.9

4.2

6.6

Locked Rotor Amps

15

22

25

22

32

Compressor Lock-Out Relay

(Normally Closed 24V) 5VA Inrush - 4V Constant

Gas Controls and Additional Data

Model

DYNA07AC

DYNA09AC

DYNA12AC

DYNA16AC

Gas (specify)

Natural or LP

Burners

1

Ignition System: Solid-State

Hot Surface

High Limit (Fixed)

190º

Blocked Flue Switch

200º

200º

200º

205º

Gas Connection Size

3/8”IPS

3/8”IPS

3/8”IPS

3/8”IPS

Gas Connection

(LH) Front or Rear

Blower/Evaporator

Model

DYNA07AC

DYNA09AC

DYNA12AC

DYNA16AC

Wheel Diameter

4.375"

4.375"

4.530"

4.530"

Wheel Width

26"

26"

26"

26"

Air Vent-Manual

70 CFM

70 CFM

70 CFM

70 CFM

Required Filter (1 Each)

6"x30-3/4"

6"x30-3/4"

6"x30-3/4" 8-1/4"x30-3/4"

Filter Type

Electrostatic/Washable Media

Specifications subject to change without notice. Installation must be in accordance with local codes and regulations.

Suburban Applied Products Dynaline™3 Model Identification And Specifications

Example

D

Y

N

A

0

7

A

C

A

0

1

2

L

F

2

0

1

0

0

Position

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

1

Unit Designation

Dynaline 3™

2

3

4

5

Nominal Cooling Capacity

07

= 7,600

09

= 9,500

12

= 11,500

16

= 15,000

6

7

System Type

AC

= Air Conditioner

8

9

Power Supply (Volts-Hz-Phase)

A

= 208/230-60-1

V

= 277-60-1

10

Nominal Heat Input

012

= 12,000

020

= 18,000

022

= 20,000

11

12

13

Fuel Type

N

= Natural Gas

L

= LP Gas

14

Gas Connection

F

= Front

15

Revision Code

20

16

17

Cabinet Color

100

= Champaign Beige

800

= Mesa Tan

416

= White

200

= Gray

18

19