Suburban Dynaline 3 A&E Manual 12/2021 Rev.2

12

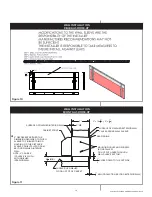

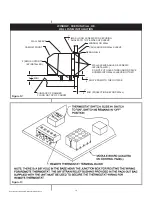

HEADER

(STEEL LINTEL IN BRICK CONSTRUCTION)

FINISHED FLOOR

SUB-FLOOR

NOTE: UNITS APPROVED FOR 0" CLEARANCE TO COMBUSTIBLE CONSTUCTIONS TOP, SIDES, AND BOTTOM. FRONT AND REAR CLEARANCE

NOT APPLICABLE AS THERE CAN BE NO CONSTRUCTION COMBUSTIBLE OR NON-COMBUSTIBLE TO THE FRONT OR REAR OF THE OPENING.

42

1

—

4

" MIN.

16

1

—

4

" MIN.

3

1

—

2

" MIN.

FRAMING

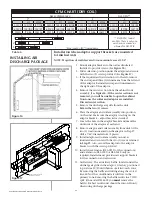

In the United States and Canada, the installation must conform with local

codes. In the absence of local codes, US installations must conform with

the current National Fuel Gas Code ANSI Z223.1 and with the National

Electrical Code ANSI/NFPA No. 70, and Canadian installations must

conform with the current CANI-B149 installation code.

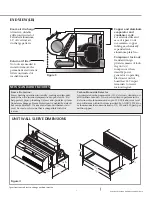

After selecting a location, inspect the wall and floor areas to determine

that there are no hidden electrical wires, piping, tubing, ducts, girders,

wall studs, etc., that might interfere with the proper installation and safe

operation of the unit and gas supply.

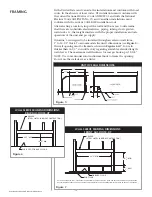

Dynaline

™

3 is designed to be installed through an exterior wall from

1" to 14-1/2" thick. To accommodate the unit’s dimensions (see

Figure 5

),

the wall opening must be framed as shown in

Figures 6 & 7

. For walls

thicker than 14-1/2", consult factory regarding available extended length

wall sleeves. The maximum wall thickness for rear gas hook-up is 12-5/8".

NOTE: Use conventional construction methods to frame the opening.

Do not use the wall sleeve as a lintel.

Figure 5

Figure 7

UNIT OVERALL DIMENSIONS

WALL SLEEVE FRAMING DIMENSIONS

FRONT GAS HOOK-UP

MIN.

1—

4

MIN.

HEADER

(STEEL LINTEL IN BRICK CONSTRUCTION)

SURFACE OF FINISHED FLOOR

42

1—

4

"

16 "

Figure 6

WALL SLEEVE FRAMING DIMENSIONS

REAR GAS HOOK-UP