3.6

Manual self-tuning

The optimization aid should be used with units on which the control parameters

shall be set without self-tuning.

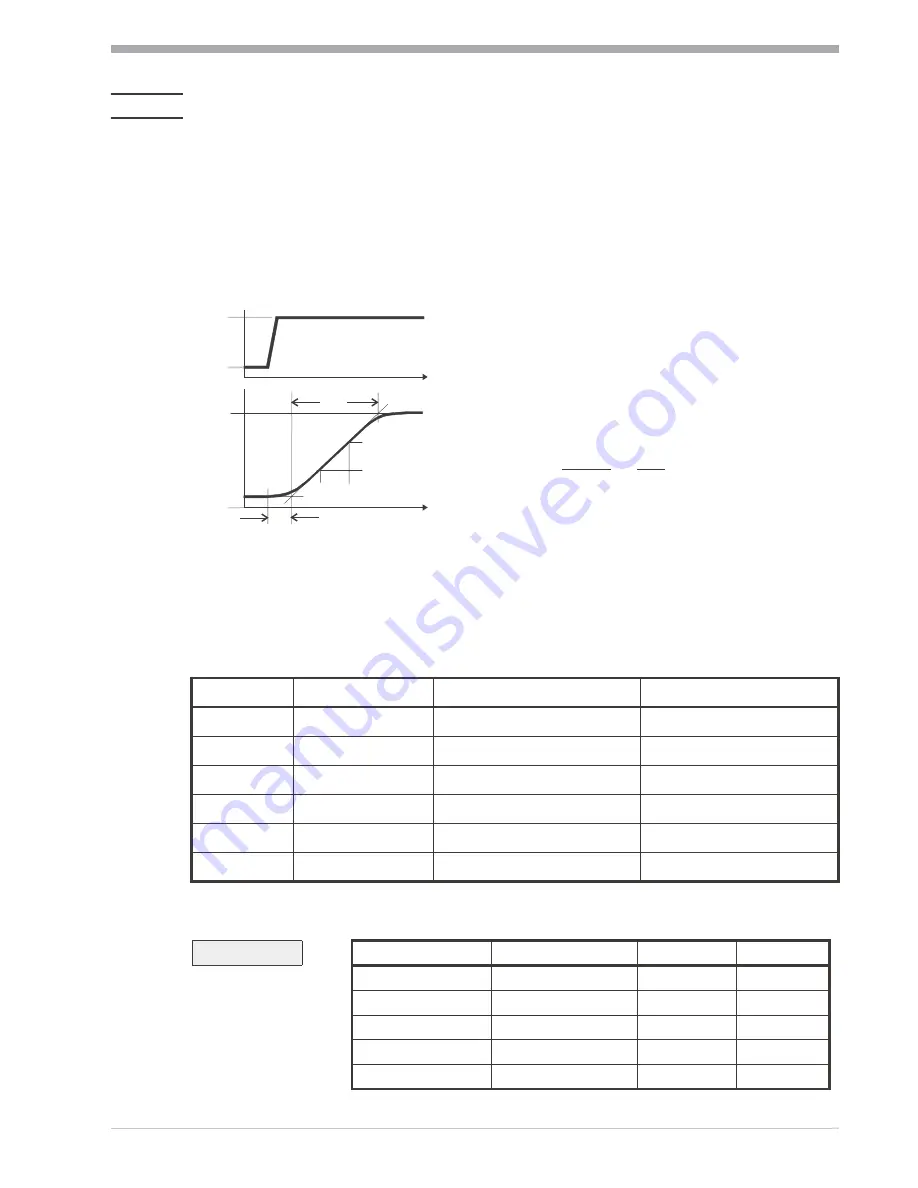

For this, the response of process variable x after a step change of correcting

variable y can be used. Frequently, plotting the complete response curve (0 to

100%) is not possible, because the process must be kept within defined limits.

Values T

g

and x

max

(step change from 0 to 100 %) or

∆

t and

∆

x (partial step

response) can be used to determine the maximum rate of increase v

max

.

The control parameters can be determined from the values calculated for delay

time T

u

, maximum rate of increase v

max

, control range X

h

and characteristic K

according to the

formulas

given below. Increase Xp, if line-out to the set-point

oscillates.

Operation

Operating manual MIR-491

19

Manual self-tuning

Formulas

K = Vmax * Tu

controller behavior

Pb1

[phy. units]

td1

[s]

ti1

[s]

With 2-point and

3-point controllers,

the cycle time must be

adjusted to

t1

/

t2

≤

0,25 * Tu

PID

1,7 * K

2 * Tu

2 * Tu

PD

0,5 * K

Tu

OFF

PI

2,6 * K

OFF

6 * Tu

P

K

OFF

OFF

3-point-stepping

1,7 * K

Tu

2 * Tu

Parameter adjustment effects

Parameter

Control

Line-out of disturbances

Start-up behaviour

Pb1

higher increased damping slower line-out

slower reduction of duty cycle

lower reduced damping

faster line-out

faster reduction of duty cycle

td1

higher reduced damping

faster response to disturbances faster reduction of duty cycle

lower increased damping slower response to disturbances slower reduction of duty cycle

ti1

higher increased damping slower line-out

slower reduction of duty cycle

lower reduced damping

faster line-out

faster reduction of duty cycle

Tu

Tg

t

x

y

100%

0%

t

Yh

Xmax

{

X

{

t

y

= correcting variable

Y

h

= control range

Tu

= delay time (s)

Tg

= recovery time (s)

X

max

= maximum process value

V

max

=

Xmax

Tg

=

{

{

x

t

=

max. rate of

increase of process value