6

the work area will lighted.

10. Work Area: Keep the floor around the machine clean and

free of foreign materials. ACCU Industries recommends the

use of anti-skid floor strips where the operator normally

stands, and that each machine has its own work area marked

off. Make certain that the work area is well-lighted and

ventilated. Provide for adequate work space around the

machine. The work area should not be readily accessible to

anyone except the operator.

11.

Do Not Overreach: Maintain a balanced stance and keep your

body under control at all times.

12.

Hand Safety: Keep hands away from moving parts when the

machine is under power. Never clear chips or debris when

the machine is under power and never use your hands to clear

the chips. Never use compressed air to clean machine; use

only a soft bristle brush or vacuum cleaner.

13.

Spindle Rotation: Rotate spindle by hand before applying

power. Be sure that the rotation of the spindle

is correct.

14.

Machining Preparation: Tighten all locks before operating the

lathe. Be sure workpiece is secured. Remove adjusting keys

and wrenches. Be sure to check to see that all adjusting

wrenches are removed from the lathe before turning the machine

on.

15.

Check Damaged Parts: Before further use of the lathe, a guard

or other part that is damaged should be carefully checked to

determine if it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any other

conditions that may affect the lathe's operation. A guard or

other part that is damaged should be properly repaired or

replaced.

16.

Maintain Tools with Care: Keep tools sharp and clean for best

and safest performance. follow instructions for lubricating

and changing accessories.

17.

Avoid Accidental Starting: Make certain that the motor

switch is in the "Off" position before connecting power

to the machine.

18.

Never Stand on Lathe: Serious injury could occur if the lathe

Summary of Contents for 8944

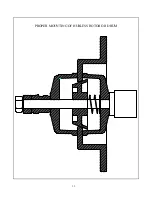

Page 18: ...15 PROPER MOUNTING OF HUBLESS ROTOR OR DRUM ...

Page 19: ...16 PROPER MOUNTING OF HUBBED ROTOR OR DRUM ...

Page 20: ...17 PROPER MOUNTING OF FLYWHEEL ...

Page 28: ......

Page 29: ...26 ...

Page 30: ...27 ...

Page 31: ...28 ...

Page 32: ...29 ...

Page 33: ...30 ...

Page 34: ...31 ...

Page 35: ...32 ...

Page 36: ......

Page 37: ...33 ...