12

4. a. Select proper size bell clamps and slide one on the arbor.

b. Slide spring on the arbor.

c. Find the centering cone adapter that fits the

center hole of the drum or rotor and slide it on the

arbor.

d. Slide the drum or rotor on the arbor and then the other

bell clamp.

e. Add necessary spacers (double tapered radius adapters may

be used as spacers), alignment washers (make sure they

are installed concave to convex), hex nut and tighten

securely. Do not jerk or over tighten. (See example on

page 15)

5. WRAP RUBBER SILENCER BAND AROUND DRUM, STARTING WITH THE

PLAIN END AND MAINTAIN TENSION UNTIL THE CLIP IS SECURED. DO

NOT ATTEMPT TO MACHINE DRUMS WITHOUT USING THE SILENCER BAND.

Silencer should be nearest open side of drum. Silencers

should also be used for rotor machining.

6. If arbor appears distorted, check for rust, burrs or chips on

cones, drum or rotor, bell clamps, spacers, arbor or other

mating surfaces.

7. Composite hubless rotors may require optional composite

rotor adapters.

Mounting Hubbed Drums or Rotors

1. Select the double tapered radius adapter that properly fits

the inside of the large bearing race. It should sit in the

race similar to a bearing and move side to side in all

directions easily. If it binds in any direction, this is an

indication of an incorrect adapter selection or a damaged

bearing race. Correct problem before proceeding.

2. Slide the double tapered radius adapter all the way onto

the arbor. If the drum or rotor contacts the lathe, a spacer

may be required between the double tapered adapter and lathe.

3. Using the same procedure as in Step 1, select the double

tapered radius adapter for the outside race.

4. Install the drum or rotor and position it on the back double

tapered radius adapter and then slide the front double tapered

radius adapter on the arbor and into the front race.

Summary of Contents for 8944

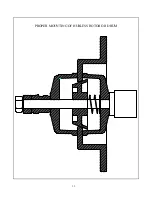

Page 18: ...15 PROPER MOUNTING OF HUBLESS ROTOR OR DRUM ...

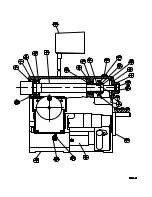

Page 19: ...16 PROPER MOUNTING OF HUBBED ROTOR OR DRUM ...

Page 20: ...17 PROPER MOUNTING OF FLYWHEEL ...

Page 28: ......

Page 29: ...26 ...

Page 30: ...27 ...

Page 31: ...28 ...

Page 32: ...29 ...

Page 33: ...30 ...

Page 34: ...31 ...

Page 35: ...32 ...

Page 36: ......

Page 37: ...33 ...